Heavy-duty high-speed crawler edge banding machine, the equipment adopts heavy-duty frame, high-standard assembly technology and famous brand accessories. The equipment runs fast, has good edge banding effect and high stability.

Overview of Heavy-duty high-speed crawler edge banding machine

| Edge band thickness | 0.4~3mm | Working pressure | 0.7mpa |

| Edge band width | 12~65mm | Total power | 24KW |

| Sheet thickness | 10~60mm | Vacuum suction diameter | φ100mm×7 |

| Board width | ≥80mm | Weight | 5000Kg |

| Feeding speed | 0~26m/min | Overall dimensions | 11500×1250×1850mm |

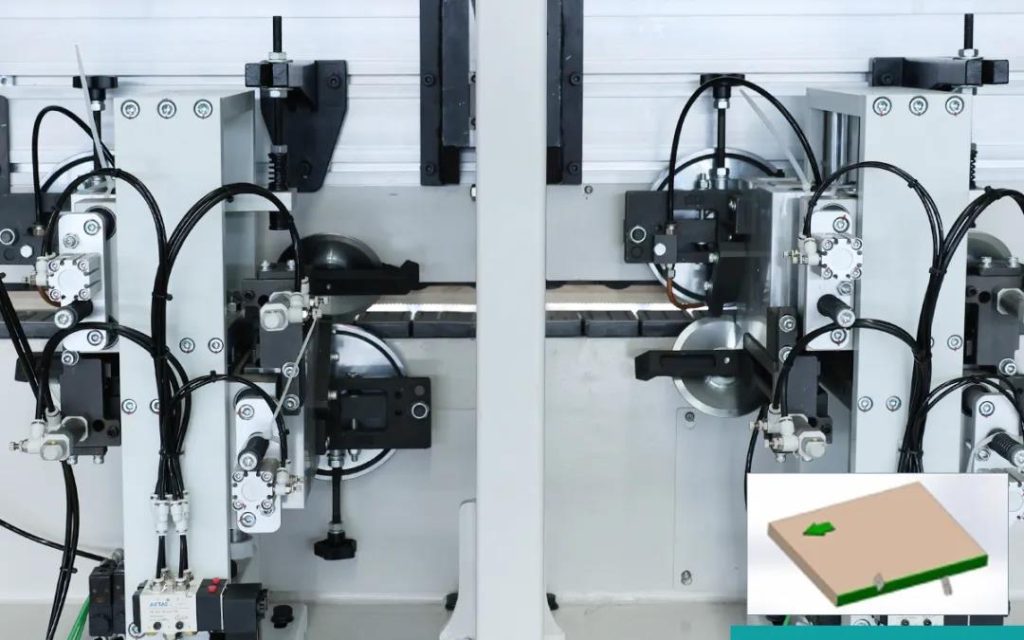

Heavy duty rack

Using thickened steel plate welding, annealing and stress relief treatment, large-scale gantry milling processing. The integrated steel structure guide rail is more than 2 centimeters thick, making the equipment run more smoothly at high speeds.

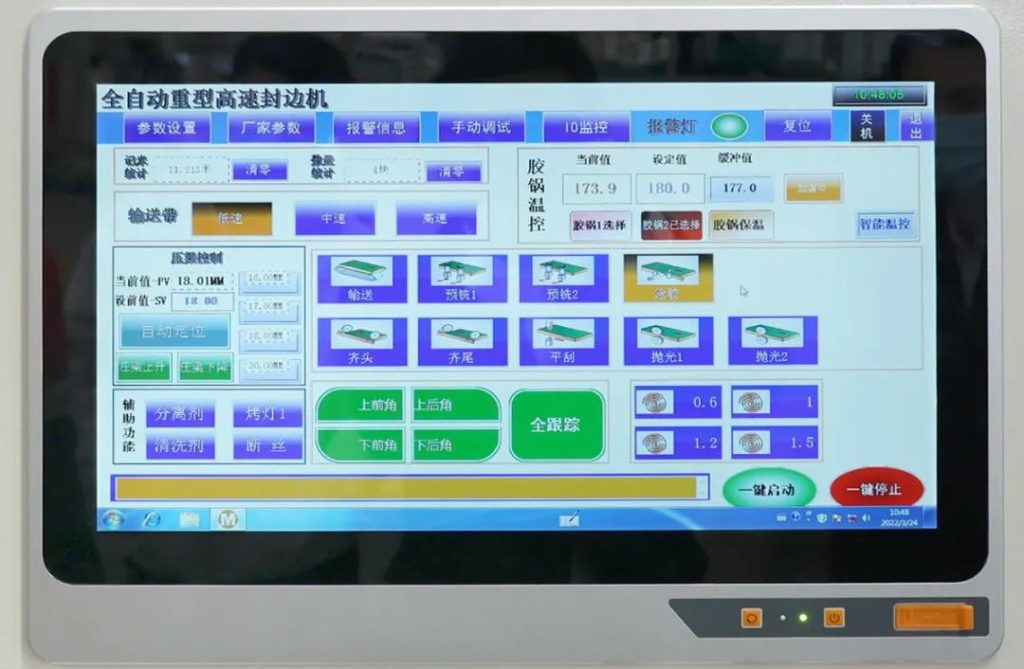

Control system

The system has high stability, visual interface, touch screen operation, all functions can be started with one click, and the edge banding function can be quickly switched.

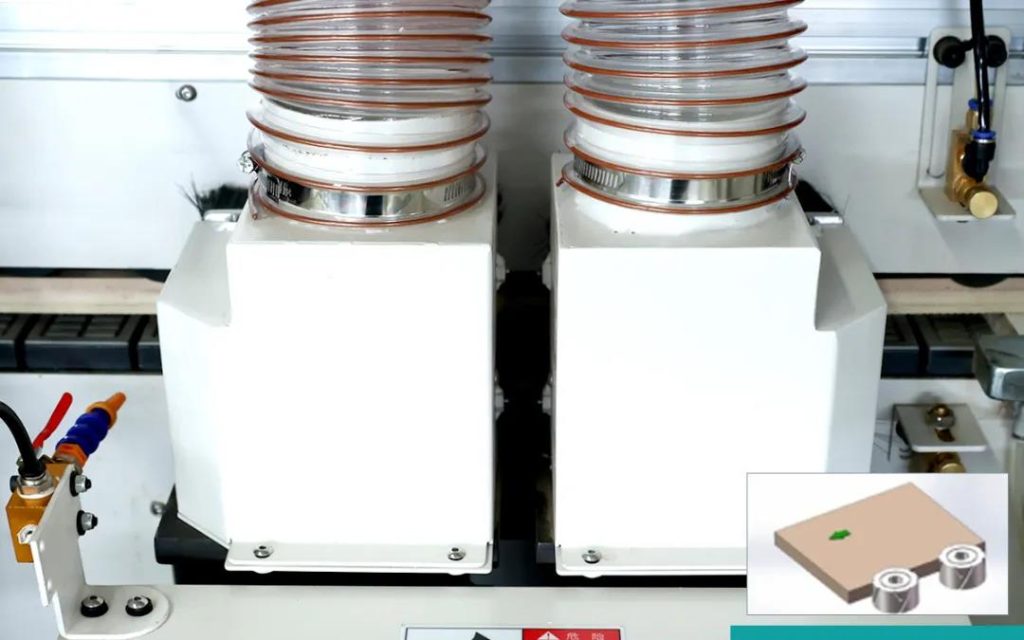

Track pressure

The track presses material, the transmission speed is fast, the material pressing is more stable, and the edge sealing effect is better.

French Schneider electrical components

Good quality, stable performance, strong anti-interference ability and long life.

Taiwan Airtac pneumatic components

Taiwan Airtac pneumatic components have good sealing performance, long life and low failure rate.

Separating agent

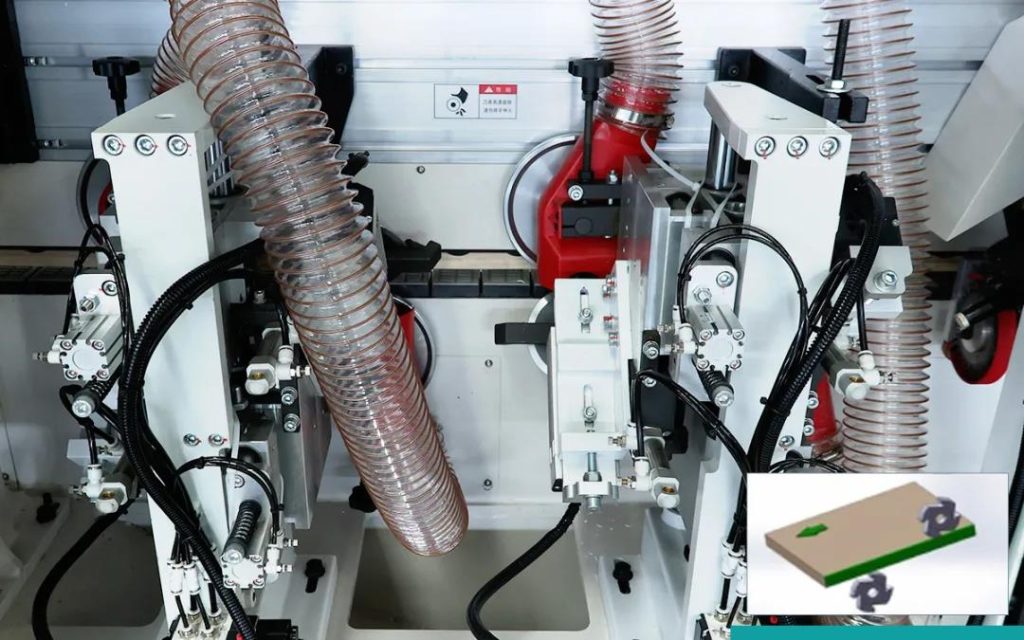

Pre -milling

Baking lamp

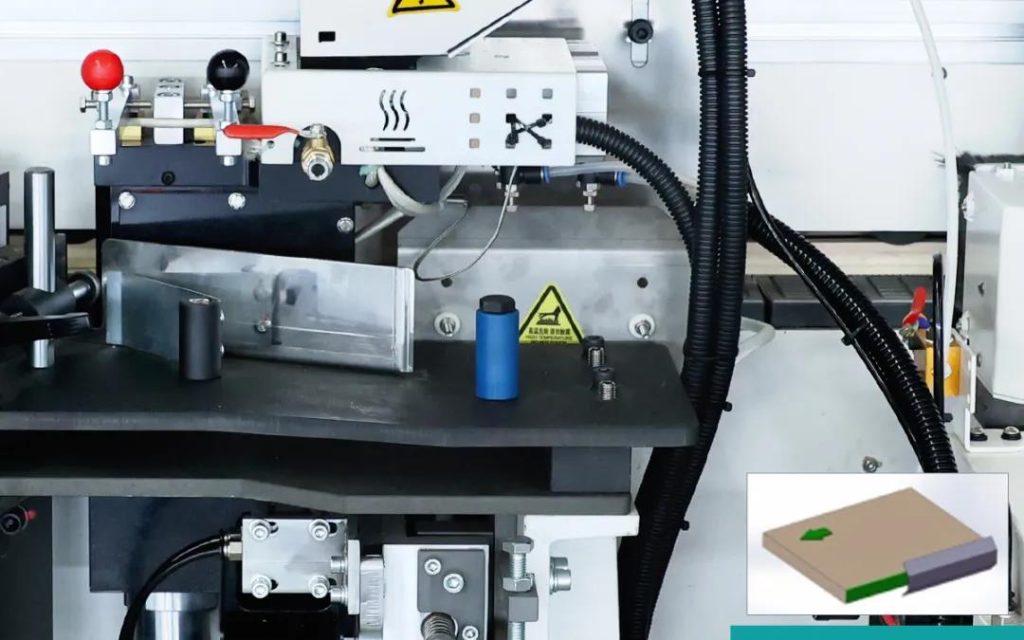

Upper sol

Six wheels with pressure clearing stickers

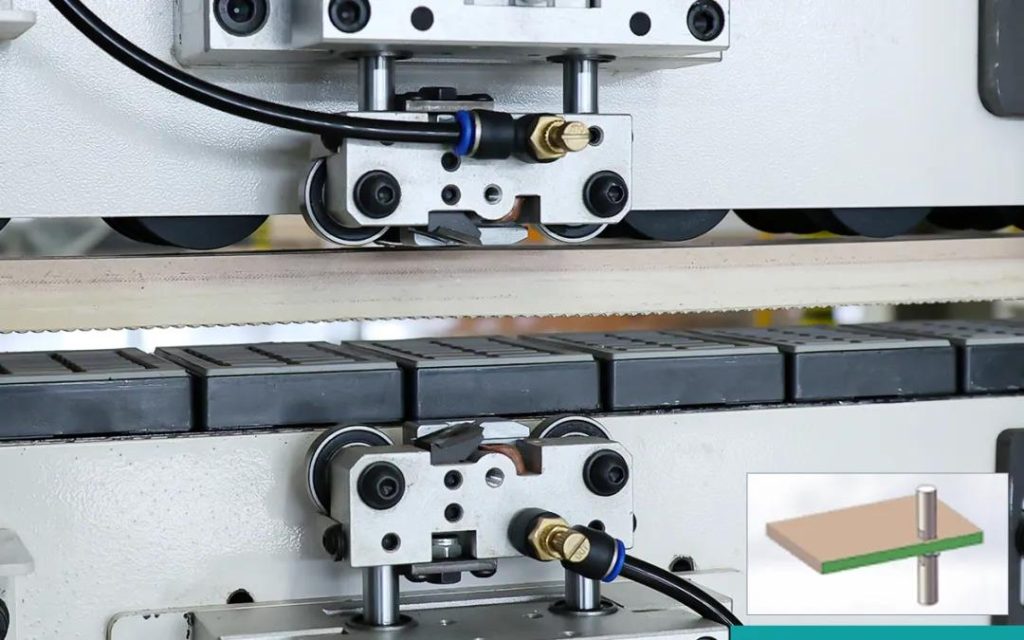

Double guide rails flush

Dual pneumatic fine repair

Four head tracking

Dual pneumatic scraping

Broken wire

Flat scraping

Cleaning

Reciprocating movement polishing

Automatic edging machines are used for pre-grinding, gluing the edging flag to the substrate, trimming the front and back edges, trimming the top and bottom flush with the substrate, scraping off any excess, and polishing the finished edges. All the work will be done on one machine, which is an upgraded version of the traditional hand-banding in modern furniture making. If you you use saw cutting, side is not perfact, so need choose pre-grinding. Each function will give you different result. So need make sure what kind of quality cabinet yo plan made. And then contact with us by mail or whatsapp. We will guide you well.

phone: +8613791007598

[email protected]