PWF 1530 five axis machine adopts Italy HSD or Hiteco five axis spindle with RTCP function ,fixed gantry and moved table. It widely used in high precision industry.

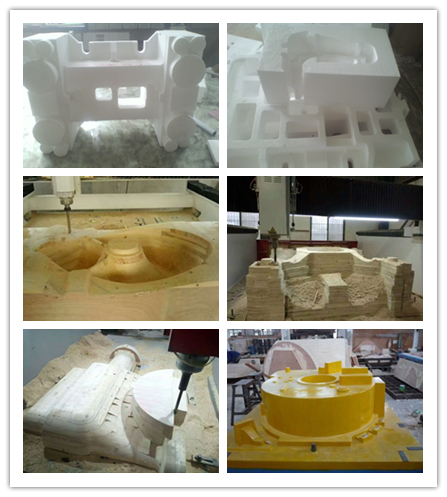

The five-axis woodworking machining center is an intelligent device that integrates digitalization and high precision. Through the three-axis linear motion of X, Y, and Z and the two-axis rotation of A and C to form a five-axis linkage system, it can complete complex processes such as curved surface carving, three-dimensional hollowing, and mortise and tenon structure cutting on solid wood, plates and other materials. Its CNC system supports the import of three-dimensional models and can accurately meet the needs of furniture carving, handicraft curved surface modeling, and special-shaped component processing. It can not only handle arc surfaces and spiral structures that are difficult to complete with traditional woodworking machinery, but also improve processing efficiency through multi-axis collaboration, adapt to customized furniture production, solid wood artwork production and other scenarios, and provide flexible and high-precision processing solutions for the woodworking industry.

KPX-150 five axis spindle water cooling

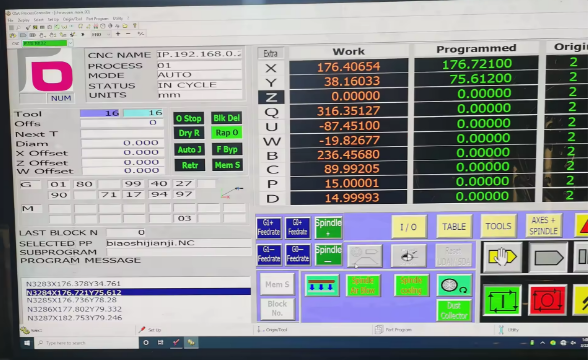

Italy OSAI five-axis control system with RTCP function

Japan Yaskawa Servo system with Japan Shimpo reduce

Moveable table with POP UP PIN for fixed position.

| Item | PWF1530 (double table) -Z750 Moving table five axis working center | |

| Travelling size for two table is same. | X axis travelling | 3200mm |

| Y axis travelling | 1500mm | |

| Z axis travelling | 700mm | |

| Table size | 1260X1260mm | |

| A axis | ±185° | |

| C axis | ±320° | |

| Max. feed speed | X axis | 60m/min |

| Y axis | 60m/min | |

| Z axis | 20m/min | |

| A axis | 160°/s | |

| C axis | 160°/s | |

| Max. working speed | 20m/min | |

| Distance between spindle nose to table | 50-750mm | |

| Body structure | Machine structure is table moving, gantry fixed | |

| Transmission | X axis adopts German grinding rack 6 grade precision rackY axis adopts Taiwan grinding rack C5 precision rack | |

| Table Structure | Cast iron table with aluminum profiles T-slot, or vacuum absorption table | |

| Spindle power and RPM | Italy spindle(S1/S6 12kw),spindle RPM 2000-24000r/min | |

| Software | UG,Mastercam,Powermill and so on. | |

| Positional Accuracy | XY axis:±0.1/1000mm,full length ≤0.15, Z axis full length ± 0.08 | |

| Repeated positioning accuracy | XY axis:±0.05、Z axis±0.04 | |

| Tool holder | HSKF 63 tool holder ER40 collet | |

| Tool Magazine | 12 carousel tool magazine | |

| Operation System | Taiwan Syntec(OSAI for optional) | |

| Operation code | G code | |

| power 、voltage 、 Air pressure | 40KW、3P AC 380V/50HZ 、≧6.5Kgf/cm² | |

| Weight | 8.5 tons | |

| Cover | 1.7 meters high, optional, not as standard Configuration | |

| machine size | width x length x height 6000x4500x5000(mm) | |

Q : What are the advantages of our five axis machines?

R: Our five axis machine is a true five-axis, using a five-axis control system with RTCP function. The spindle adopts a real five-axis from a well-known Italian brand HSD or Hiteco, which can ensure the accuracy of processing molds.

phone: +8613791007598

[email protected]