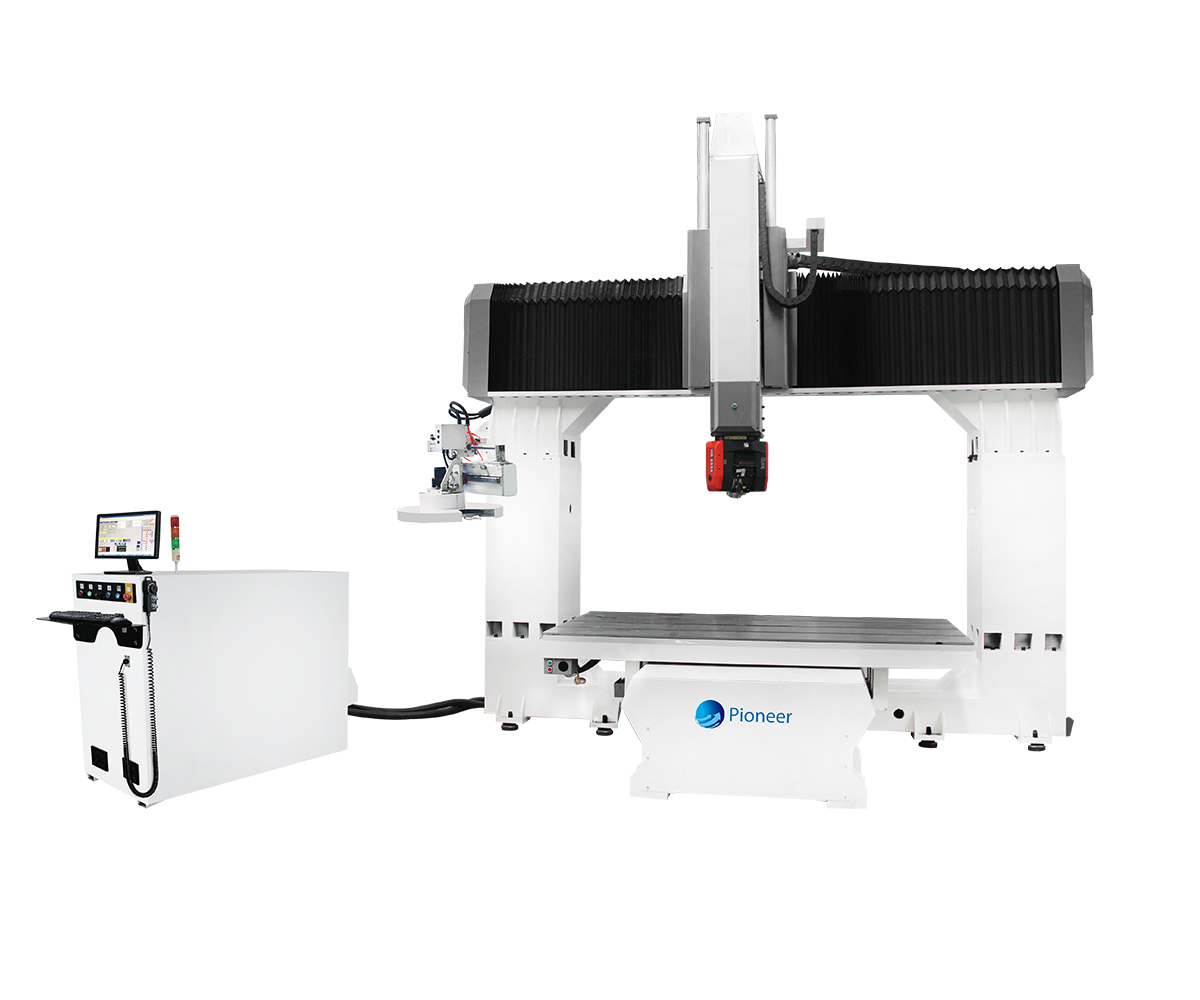

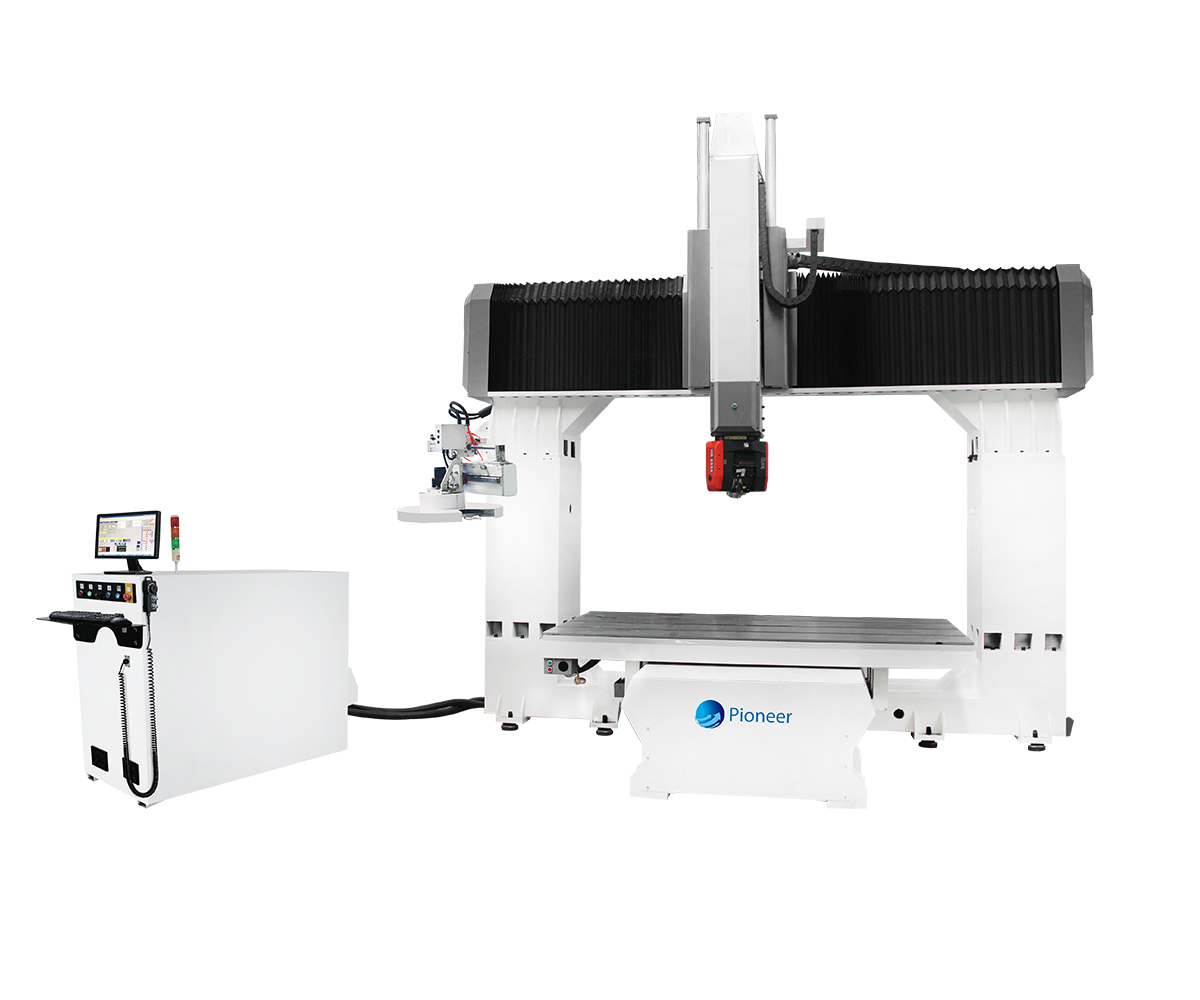

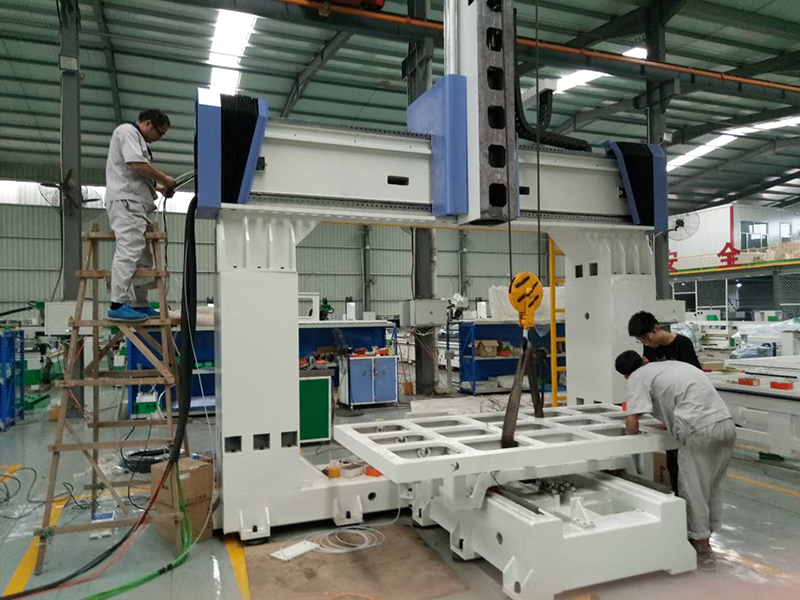

PWF 1530 five axis machine adopts Italy HSD or Hiteco five axis spindle with RTCP function ,fixed gantry and moved table. It widely used in high precision industry.

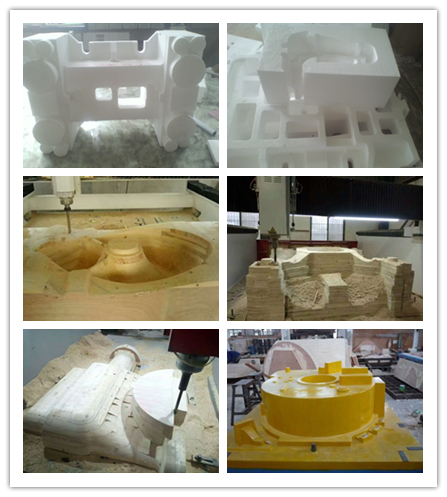

Gantry fixed five-axis linkage machining center, also called the five-axis machining center, is a machining center with high technological content and high precision specially used for processing complex curved surfaces. This machining center system plays an important role in a country’s aviation, aerospace, military, scientific research, and precision Industries such as medical devices and high-precision medical equipment have a decisive influence. At present, the five-axis linkage CNC machining center system is the only means to solve the processing of impellers, blades, marine propellers, heavy-duty generator rotors, steam turbine rotors, large diesel engine crankshafts, etc.

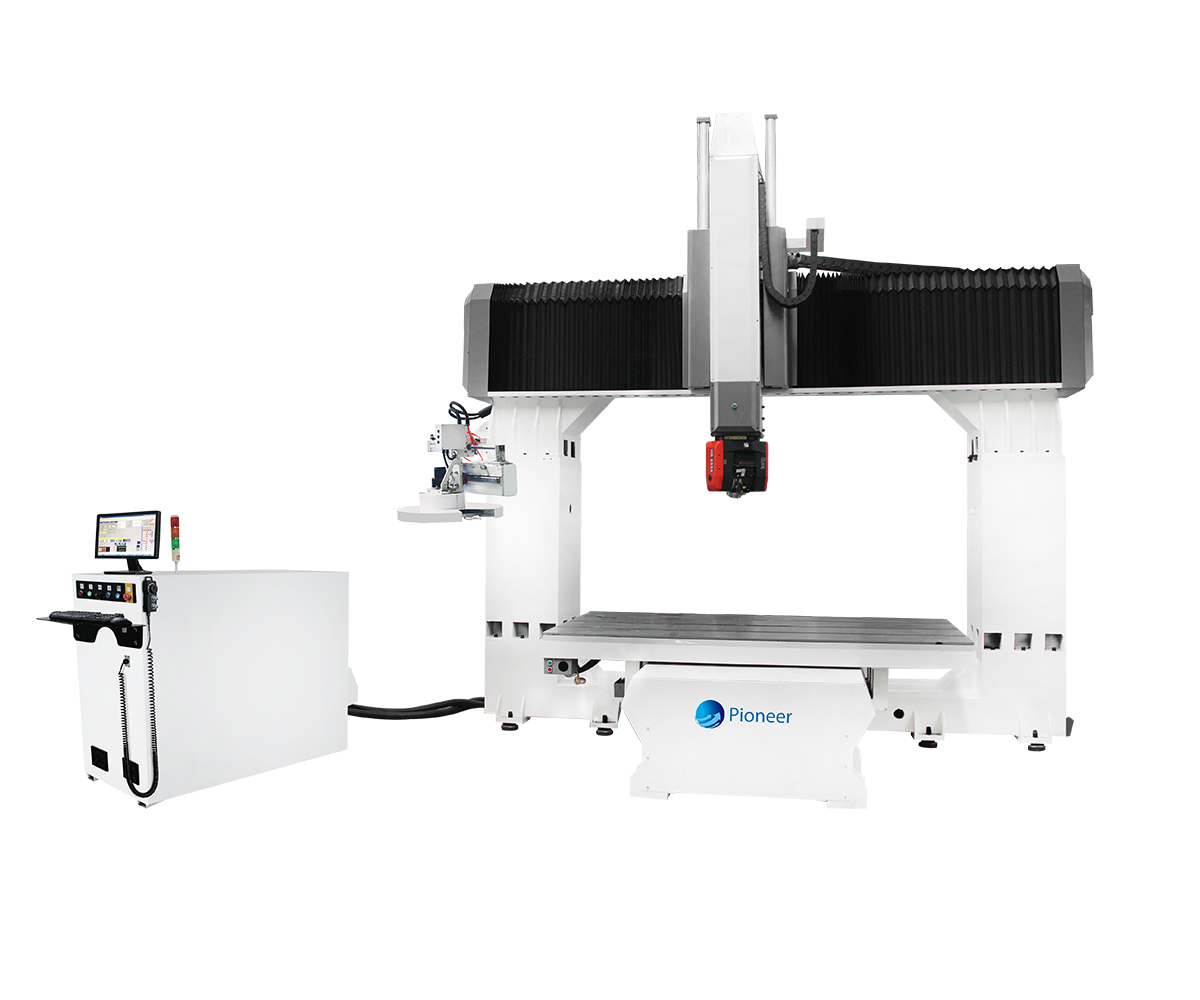

KPX-150 five axis spindle water cooling

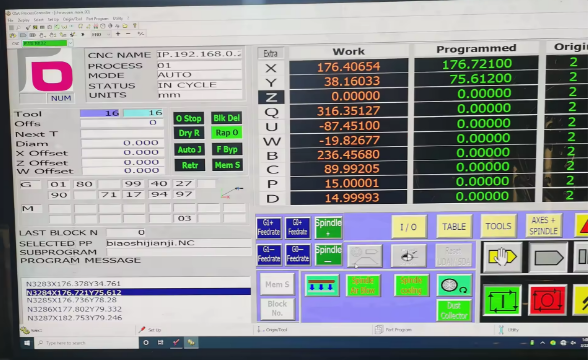

Italy OSAI five-axis control system with RTCP function

Japan Yaskawa Servo system with Japan Shimpo reduce

Moveable table with POP UP PIN for fixed position.

| Item | PWF1530 (double table) -Z750 Moving table five axis working center | |

| Travelling size for two table is same. | X axis travelling | 3200mm |

| Y axis travelling | 1500mm | |

| Z axis travelling | 700mm | |

| Table size | 1260X1260mm | |

| A axis | ±185° | |

| C axis | ±320° | |

| Max. feed speed | X axis | 60m/min |

| Y axis | 60m/min | |

| Z axis | 20m/min | |

| A axis | 160°/s | |

| C axis | 160°/s | |

| Max. working speed | 20m/min | |

| Distance between spindle nose to table | 50-750mm | |

| Body structure | Machine structure is table moving, gantry fixed | |

| Transmission | X axis adopts German grinding rack 6 grade precision rackY axis adopts Taiwan grinding rack C5 precision rack | |

| Table Structure | Cast iron table with aluminum profiles T-slot, or vacuum absorption table | |

| Spindle power and RPM | Italy spindle(S1/S6 12kw),spindle RPM 2000-24000r/min | |

| Software | UG,Mastercam,Powermill and so on. | |

| Positional Accuracy | XY axis:±0.1/1000mm,full length ≤0.15, Z axis full length ± 0.08 | |

| Repeated positioning accuracy | XY axis:±0.05、Z axis±0.04 | |

| Tool holder | HSKF 63 tool holder ER40 collet | |

| Tool Magazine | 12 carousel tool magazine | |

| Operation System | Taiwan Syntec(OSAI for optional) | |

| Operation code | G code | |

| power 、voltage 、 Air pressure | 40KW、3P AC 380V/50HZ 、≧6.5Kgf/cm² | |

| Weight | 8.5 tons | |

| Cover | 1.7 meters high, optional, not as standard Configuration | |

| machine size | width x length x height 6000x4500x5000(mm) | |

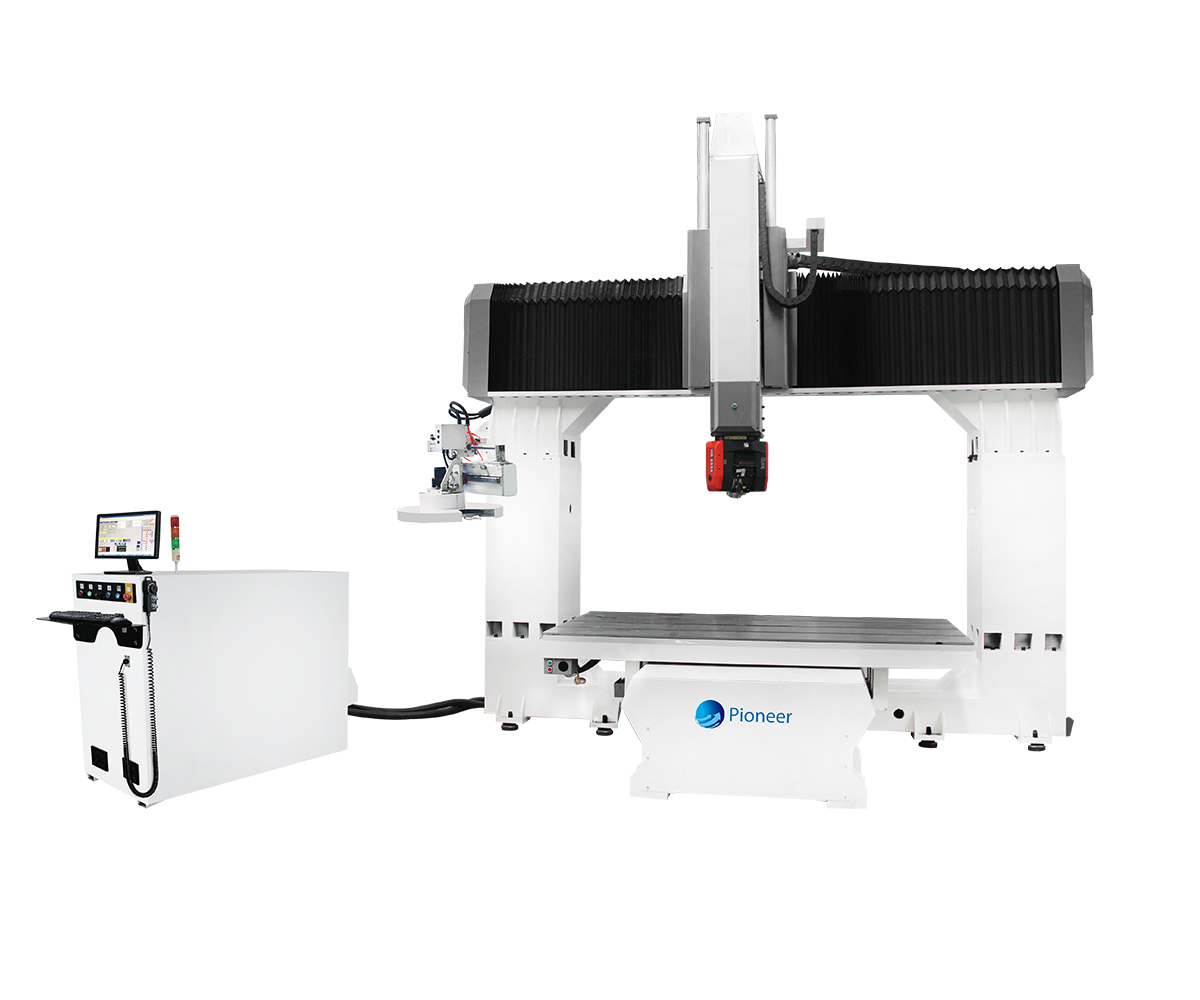

Q : What are the advantages of our five axis machines?

R: Our five axis machine is a true five-axis, using a five-axis control system with RTCP function. The spindle adopts a real five-axis from a well-known Italian brand HSD or Hiteco, which can ensure the accuracy of processing molds.

phone: +8613791007598

[email protected]