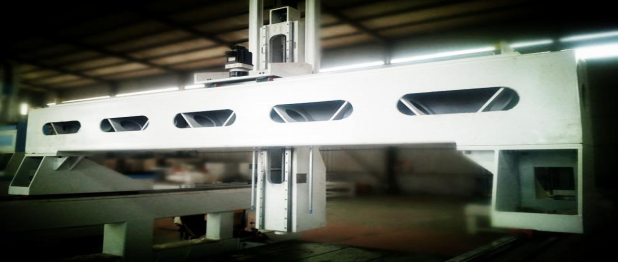

CNC movable gantry five axis working center adopts a gantry structure body, which has high rigidity and stability, ensuring high-precision machining.

Mobile gantry frame structure, fixed worktable, the beam moves longitudinally

along the column guide, the milling head slide moves left and right along the

beam guide, and the milling head ram moves vertically along the slide guide.

Beam adopt a closed box-shaped structure, and there are reinforcing ribs in reasonable internal layout. At the same time, it is subjected to aging treatment to eliminate stress and achieve the best stable state.

Italy Osai control system with RTCP

Japan Yaskawa servo XY1.5kw Z1.5kw with brake

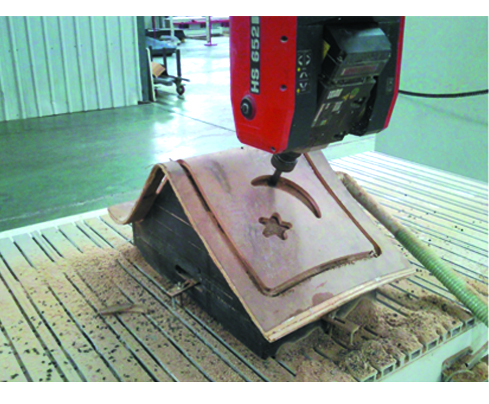

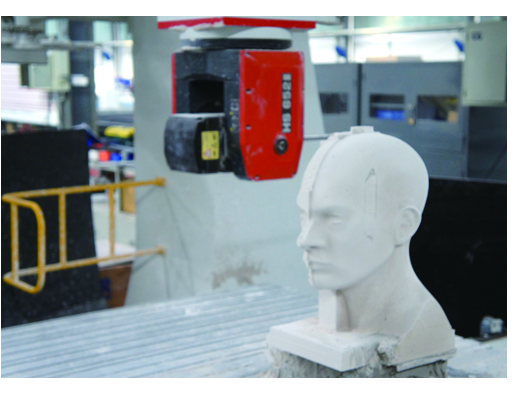

5 axis use 12kw Italy HITECO ATC water cooling spindle with automatic tool clamping device

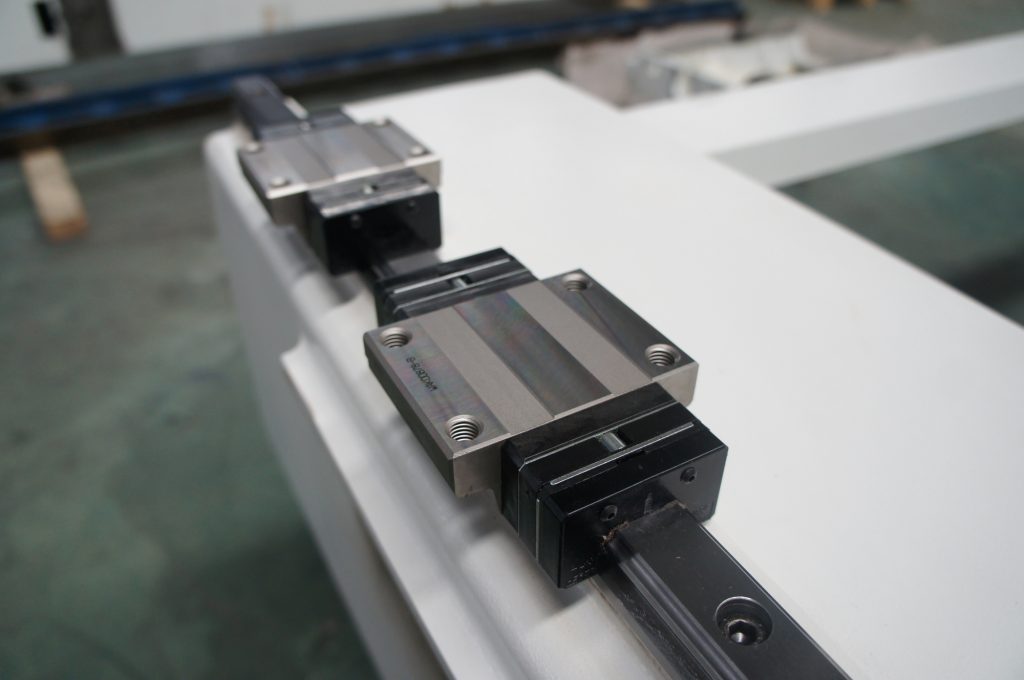

Taiwan PMI linear guide rails for Y axis 45, X 35 Z 30

Taiwan Delta inverter 15kw

| Stroke Size (mm) | X: 3000-12000 | 5 Axis Working Size (mm) | X: 2000-11000 | Spindle | Italy HITECO 15Kw Spindle |

| Y: 2000-3500 | Y: 1000-2500 | Spindle Speed | 24000rpm/min | ||

| Z: 1000-2000 | Z:750- 1600 | Spindle Cone | HSK 63F | ||

| A Axis | ±120° | Drive Type | XY: Incline Rack & Pinion Z all adopt high precision ball screws | ||

| C Axis | ±360° | Work Model | AC Servo Drive | ||

| Max Working Speed X/Y/Z(m/min) | 40/40/10 | Work Table Type | No | ||

| Max Rapid Speed X/Y/Z(m/min) | 60/60/20 | Air Pressure (kgf/cm2) | 0.6~0.7 | ||

| Positioning Accuracy X/Y/Z (mm/m) | 0.03/0.03/0.03 | Total Power (KVA) | 42 | ||

| Repeatability X/Y/Z (mm/m) | 0.02/0.02/0.02 | Gross Weight (T) | 30 | ||

phone: +8613791007598

[email protected]