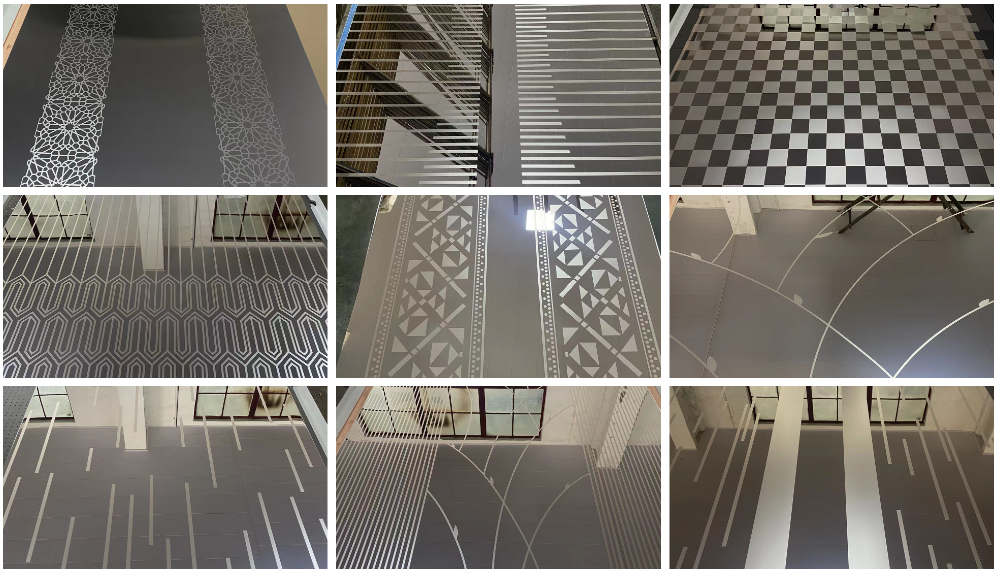

★ Replace chemical etching, environmental protection no pollution ★ No consumables for life,fast processing speed, high work efficiency, 1300*2500 size sheet about 20 minutes ★ Laser etching machine CNC control system with 1000 multi-image For choosing, also can design by yourself ★ Laser life of 100,000 hours, no special maintenance, one hour power consumption 2-3 KWH ★ Can be etched on metal materials such as stainless steel, aluminum, alloy and copper ★ Pollution-Free Precision: Ensures a clean and safe working environment. ★Diverse Intricacies: Achieve intricate designs that elevate metal craftsmanship. ★Seamless Precision:Advanced laser movement system ensures seamless work completion without split lines. ★Cost-Efficient Dynamics: Operate multiple machines with a two-worker team, optimizing labor costs and production time

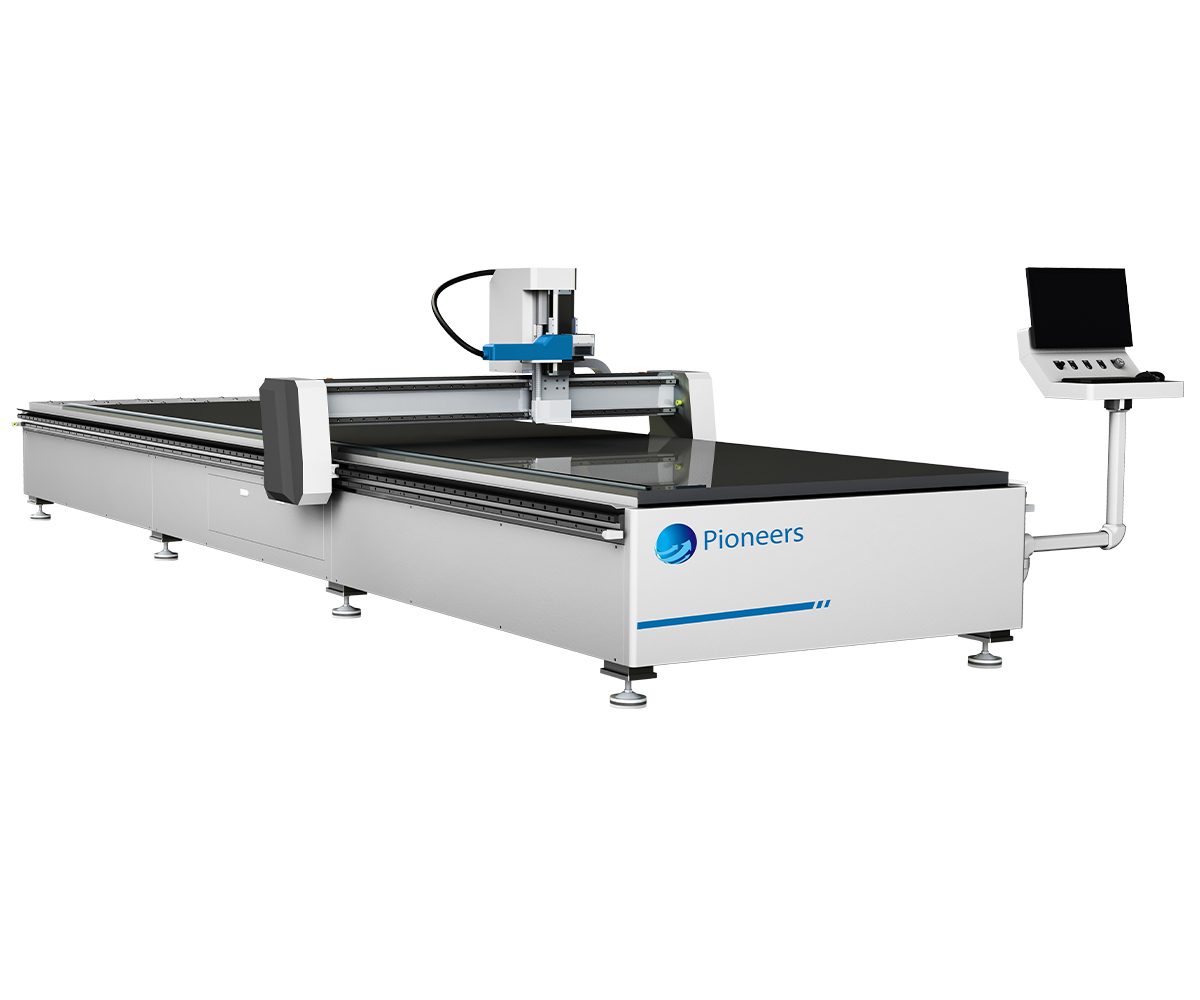

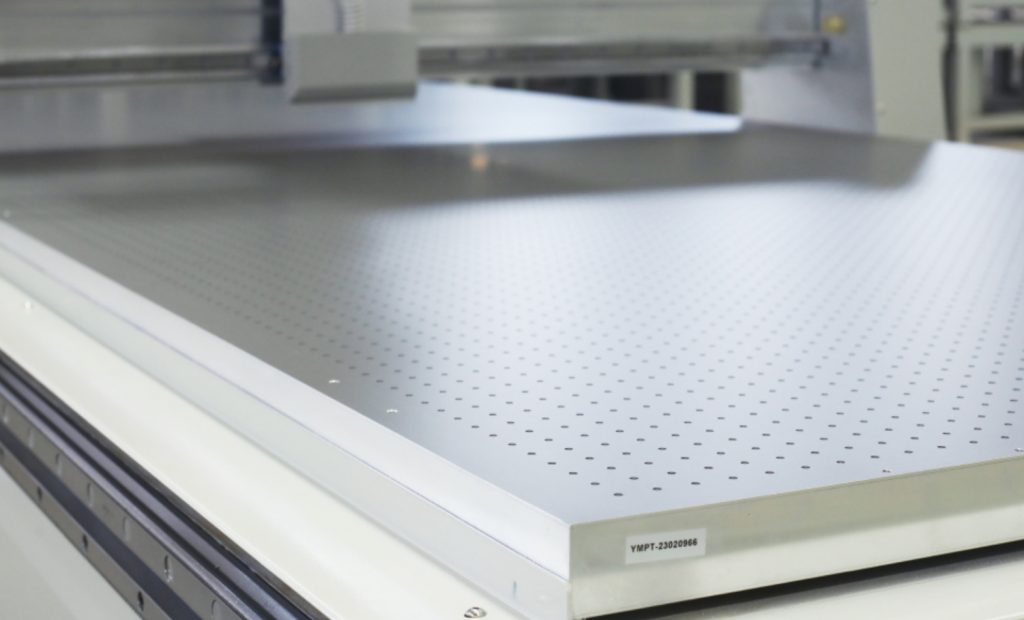

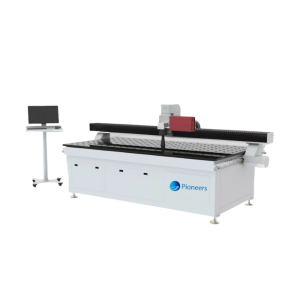

Thick aluminum table offers stable and solid platform

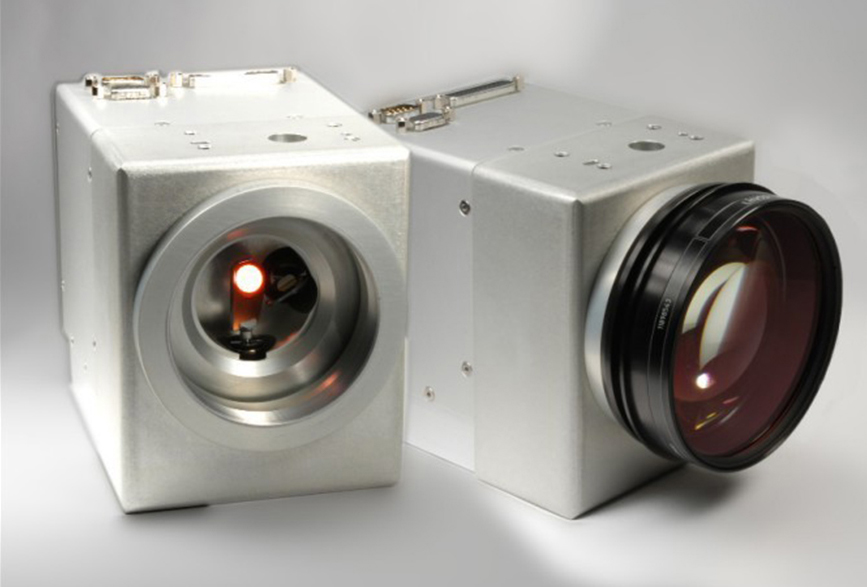

High precision and high speed Germany galvanometer

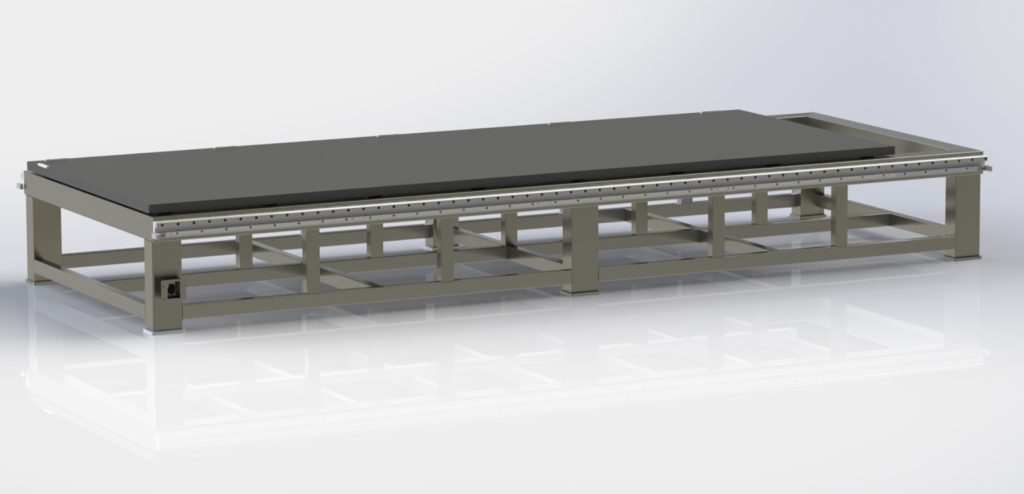

High precision transmission system using linear rail and servomotor

Superior machine body design

| Model No. | PLE 1310/1325/1530 |

| Table size(mm): | 1300*1000/1300*2500/1500*3000 |

| Working way | Laser Etching |

| Laser Power(W) | 100 W |

| Material thickness (mm) | 0.5-80 |

| Working precision (mm) | ≤0.02 |

| Etching depth (mm) | 0.03-0.05 |

| Etching speed (mm/s) | 10-10000 |

| Files format | DXF 、PLT、BMP 、 EPS 、TIF、 |

| Material fixed way: | Aluminum vacuum table |

| Power of vacuum table | 7.5KW |

| X Y Z travelling system | X Y Z adopt Japan Panasonic servo system |

| Control System | Taiwan Syntec Follow-up laser control system |

| Machine size(mm): | 3680*2800*1500 |

| Machine Weight | 1200KG |

| Total power: | 1KW |

| Voltage | 220V/50HZ(machine)380V/50HZ( vacuum table) |

phone: +8613791007598

[email protected]