/Pioneers-oscillating-knife-cutting-machine-for-composite-material-application-pd44725501.html

Pioneers oscillating knife cutting machine for composite material application video:

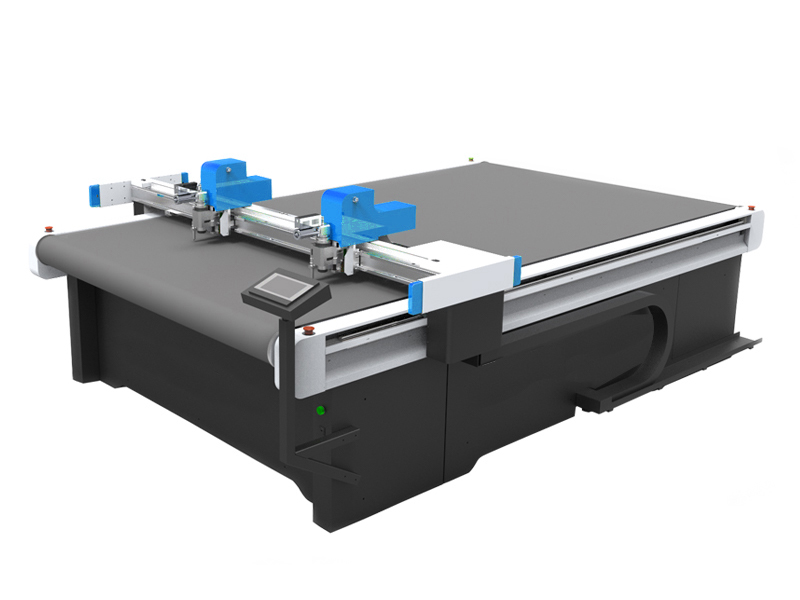

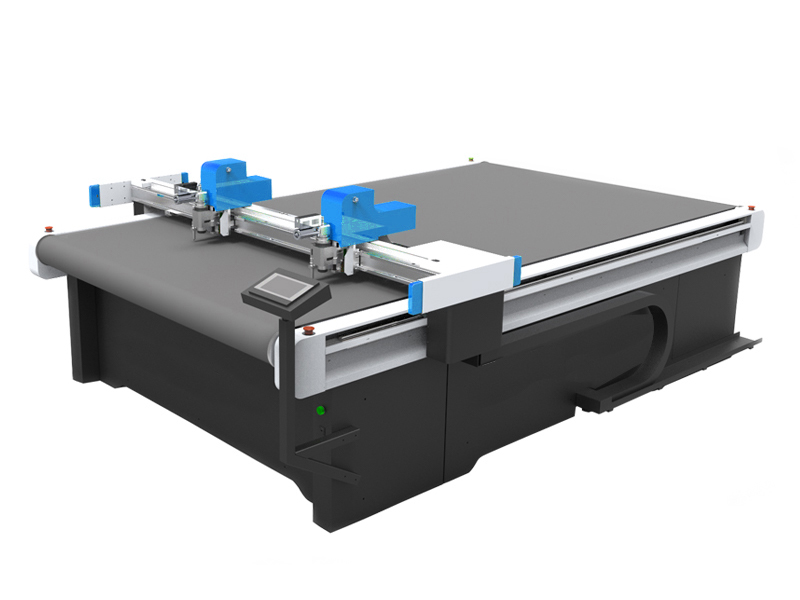

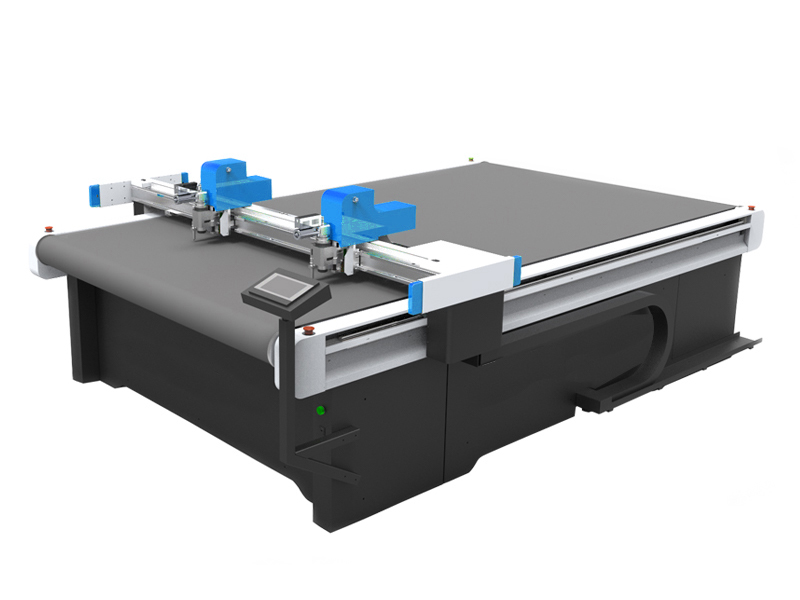

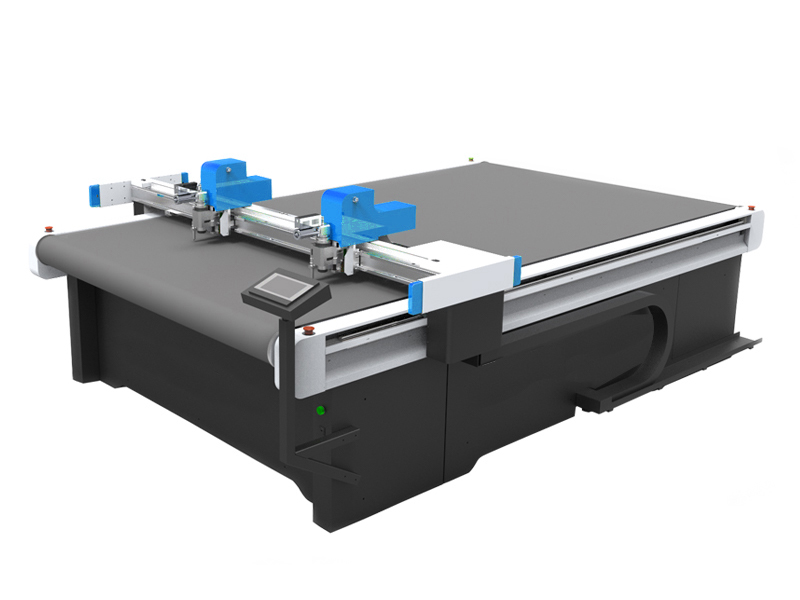

1625 oscillating knife cutting Machine Details£º

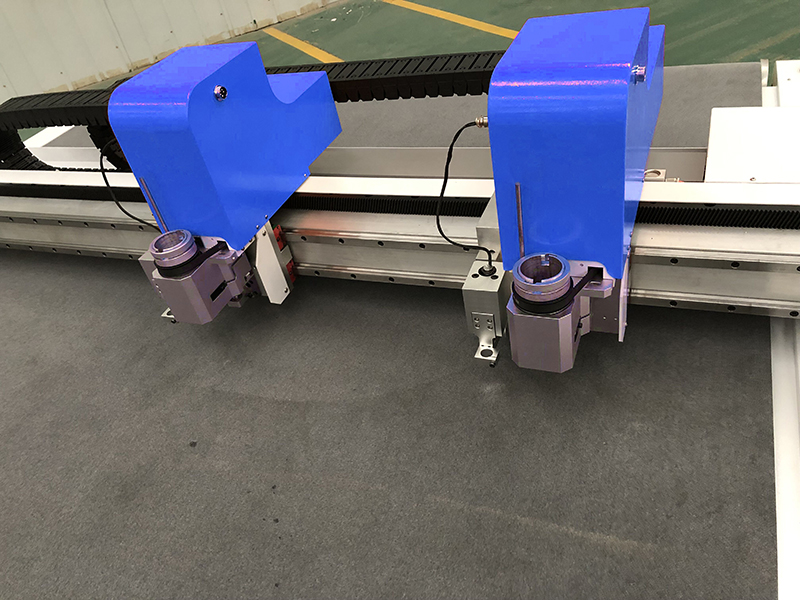

New modular tool holder design

When customers increase product types, they only need to buy tool holders and tools to use, which provides convenience for customers to upgrade their products.

Taiwan PMI rail

Adopt Taiwan PMI rail, high precision, low failure rate, long service life and low noise.

Rack

Compared with belt drive, the equipment adopts rack and pinion drive, which has larger bearing capacity, higher transmission precision, faster transmission speed and longer service life.

Control screen

The control system includes a controller and a liquid crystal touch panel, which makes the cutting process efficient and perfect, and the control panel adopts an English interface, which is easy to operate.

Safety devices

Equipped with infrared automatic sensing device and four emergency stop buttons, the safety device provides a safe working environment.

Bed structure

The whole machine adopts 5mm thick square tube, the overall welding process, and the imported milling machine processing, which ensures the smoothness of the guide rail surface and the rack surface

Technology Parameters£º

| Model | TY-1625P | customization | |

| Working size | 1600×2500 | Size customization | |

| Cutting thickness | <100mm(depending on material£© | Cutting accuracy | ±0.1mm |

| Compatible formats | DXF,PLT | Material fixing method | Vacuum adsorption |

| Maximum cutting speed | 1200mm/s | Rated power |

11KW |

| Cutting head |

Vibrating knife,Round knife | ||

| Operating Features | 24 hours continuous work, offline work | ||

| safety devices | Infrared shooting, emergency stop button | ||

| Applicable materials |

Carbon fiber, glass fiber, sandwich cloth, brushed cloth, various flexible materials such as PVC, XPE, fabrics, foam composites, PVC rolls, polyurethane leather, PU Leather, genuine leather, silicone, rubber, etc. |

||

Tool selection£º

Round knife

The circular blade is driven by a motor and rotates at high speed to cut the material. It does not require more force on the material.

Applicable materials: breathable materials, thin fur materials. Speed: 12000/8000 times/min

Vibrating knife

Vibrating knife

Vibrating knives are the most widely used cutting tools. The cutting principle is to realize cutting by driving the blade to move up and down through high-frequency vibration. Adopt Swiss Maxon brushless DC motor. The high-frequency vibrating knife tool can make the cutting surface of the material smoother, the cutting effect is better, the efficiency is higher, and the service life of the blade is increased.

Pneumatic Knife

The Pneumatic Vibrating Knife Cutting Tool is an air-driven tool that is particularly suitable for cutting hard, dense materials, but can also handle soft, thicker materials. Using considerable air pressure, combined with a 10mm stroke, allows this tool to achieve the required force in harsh applications.

Applications£º

FAQ:

Q1:How are Pioneers wood CNC £¬oscillating knife cutting machine and laser cutting machines?

A1£ºThey insist to do high quality machine with competive price. And the important thing is they can do with your special requests, they do what customer want.

Q2: What kind of work this oscillating knife cutting machine can do?

A2: Whether it is fabric, leather, soft glass or printed carpet, it can meet your cutting requirements, in the soft glass tablecloth industry, chamfer cutting can be realized.

Introduction Of the Company:

Pioneers oscillating knife cutting machine for composite material application video:

1625 oscillating knife cutting Machine Details£º

New modular tool holder design

When customers increase product types, they only need to buy tool holders and tools to use, which provides convenience for customers to upgrade their products.

Taiwan PMI rail

Adopt Taiwan PMI rail, high precision, low failure rate, long service life and low noise.

Rack

Compared with belt drive, the equipment adopts rack and pinion drive, which has larger bearing capacity, higher transmission precision, faster transmission speed and longer service life.

Control screen

The control system includes a controller and a liquid crystal touch panel, which makes the cutting process efficient and perfect, and the control panel adopts an English interface, which is easy to operate.

Safety devices

Equipped with infrared automatic sensing device and four emergency stop buttons, the safety device provides a safe working environment.

Bed structure

The whole machine adopts 5mm thick square tube, the overall welding process, and the imported milling machine processing, which ensures the smoothness of the guide rail surface and the rack surface

Technology Parameters£º

| Model | TY-1625P | customization | |

| Working size | 1600×2500 | Size customization | |

| Cutting thickness | <100mm(depending on material£© | Cutting accuracy | ±0.1mm |

| Compatible formats | DXF,PLT | Material fixing method | Vacuum adsorption |

| Maximum cutting speed | 1200mm/s | Rated power |

11KW |

| Cutting head |

Vibrating knife,Round knife | ||

| Operating Features | 24 hours continuous work, offline work | ||

| safety devices | Infrared shooting, emergency stop button | ||

| Applicable materials |

Carbon fiber, glass fiber, sandwich cloth, brushed cloth, various flexible materials such as PVC, XPE, fabrics, foam composites, PVC rolls, polyurethane leather, PU Leather, genuine leather, silicone, rubber, etc. |

||

Tool selection£º

Round knife

The circular blade is driven by a motor and rotates at high speed to cut the material. It does not require more force on the material.

Applicable materials: breathable materials, thin fur materials. Speed: 12000/8000 times/min

Vibrating knife

Vibrating knife

Vibrating knives are the most widely used cutting tools. The cutting principle is to realize cutting by driving the blade to move up and down through high-frequency vibration. Adopt Swiss Maxon brushless DC motor. The high-frequency vibrating knife tool can make the cutting surface of the material smoother, the cutting effect is better, the efficiency is higher, and the service life of the blade is increased.

Pneumatic Knife

The Pneumatic Vibrating Knife Cutting Tool is an air-driven tool that is particularly suitable for cutting hard, dense materials, but can also handle soft, thicker materials. Using considerable air pressure, combined with a 10mm stroke, allows this tool to achieve the required force in harsh applications.

Applications£º

FAQ:

Q1:How are Pioneers wood CNC £¬oscillating knife cutting machine and laser cutting machines?

A1£ºThey insist to do high quality machine with competive price. And the important thing is they can do with your special requests, they do what customer want.

Q2: What kind of work this oscillating knife cutting machine can do?

A2: Whether it is fabric, leather, soft glass or printed carpet, it can meet your cutting requirements, in the soft glass tablecloth industry, chamfer cutting can be realized.

Introduction Of the Company:

phone: +48 501 944 934

[email protected]