At the moment when smart homes are booming, smart mirrors, as innovative products that combine high technology and practical functions, are gradually entering thousands of households. From getting up in the morning to check the weather and news, to understanding the skin condition before going to bed at night, smart mirrors have become a powerful assistant for modern home life with their convenient interactive experience. In the production process of smart mirrors, smart mirror sandblasting machines play a vital role, and their appearance has brought revolutionary changes to the manufacturing of smart mirrors.

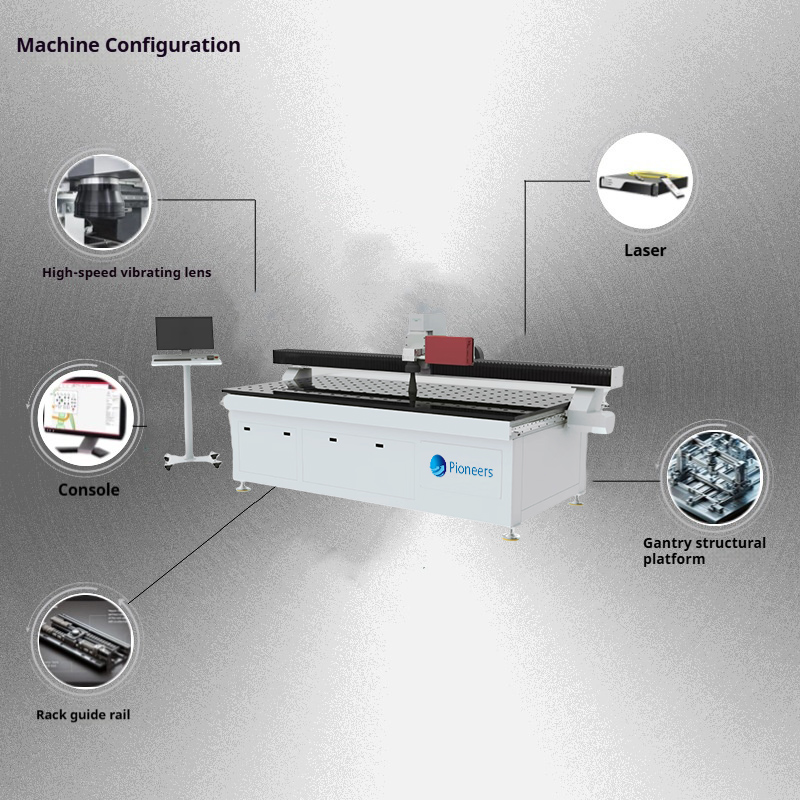

Smart mirror sandblasting machines are mainly used to sand the mirror surface of smart mirrors. Its working principle is to use high-energy laser beams to precisely act on the glass surface. During operation, the laser beam instantly releases powerful energy, causing the tiny particles on the glass surface to quickly absorb energy, and then melt, vaporize or evaporate, so as to achieve fine processing of the glass surface and form a uniform and delicate frosted effect. Compared with traditional mechanical sandblasting or chemical dissolution processes, laser sandblasting has incomparable advantages.

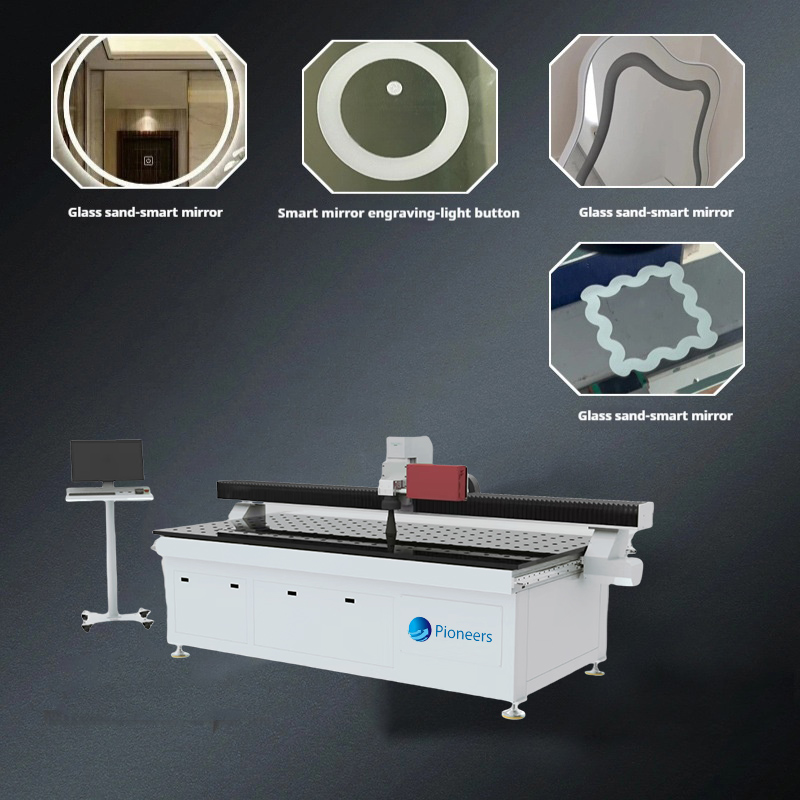

In terms of accuracy, the spot of the laser beam is extremely small, and it can be accurately focused on a specific area on the glass surface to achieve micron-level processing accuracy. This means that the smart mirror sandblasting machine can easily create extremely complex and fine patterns and textures to meet consumers’ needs for personalized and customized smart mirrors. This high-precision processing capability is particularly important when producing artistic carved smart mirrors or branded smart mirrors with unique logos. It is difficult for traditional processes to achieve such a fine level, but the smart mirror sandblasting machine can do it with ease.

In terms of efficiency, the smart mirror sandblasting machine is even more outstanding. Traditional mechanical sandblasting requires high-pressure air to spray abrasive materials such as sand or silicon carbide onto the surface of the smart mirror. The whole process is not only slow, but also frequently replaces abrasives and cleans equipment, which greatly affects production efficiency. Chemical dissolution uses hydrofluoric acid solution to dissolve the surface of the smart mirror, which takes a long time and the subsequent processing procedures are cumbersome. The smart mirror sandblasting machine uses a laser beam for processing, which is extremely fast. It can complete operations such as drilling and sandblasting in a few seconds, greatly shortening the production cycle. When mass-producing smart mirrors, it can significantly increase the company’s production capacity and bring more economic benefits to the company.

Environmental protection is also a highlight of the smart mirror sandblasting machine. Traditional sandblasting process will produce a lot of dust, which will not only cause serious pollution to the production environment, but also endanger the health of operators. Chemical dissolution will produce harmful chemical wastewater, which will cause great damage to the environment if not handled properly. In the process of laser sandblasting, no dust, wastewater and other pollutants are produced, which conforms to the current green and environmentally friendly production concept and provides a strong guarantee for the sustainable development of enterprises.

The application range of smart mirror sandblasting machine is very wide. In the field of home furnishing, it is used to produce smart bathroom mirrors, makeup mirrors, dressing mirrors, etc., making home life more intelligent and convenient. In commercial places, such as hotel lobbies, shopping mall fitting rooms, etc., the smart mirrors manufactured by smart mirror sandblasting machines can bring unique experience to customers and enhance the sense of technology and service quality of the place. Smart mirror sandblasting machines can also be used in other fields such as medical care and transportation to manufacture observation mirrors on medical equipment and smart rearview mirrors in cars.

With the continuous advancement of science and technology, smart mirror sandblasting machines are also continuing to innovate and develop. In the future, it will move towards higher precision, higher efficiency and more intelligence. For example, by introducing artificial intelligence technology, automatic monitoring and intelligent adjustment of the processing process can be achieved, further improving processing quality and production efficiency. I believe that with the help of smart mirror sandblasting machines, smart mirrors will be widely used in more fields, bringing more surprises and convenience to people’s lives.