The difference between laser etching and traditional chemical etching.Etching technology has always played a vital role. However, with the continuous development of science and technology, traditional chemical etching technology is gradually being replaced by laser etching technology. Although the two technologies have the same goal, they have significant differences in principle, precision, cost, environmental protection and other aspects.

Laser Etching and Traditional Chemical Etching Technical Principle

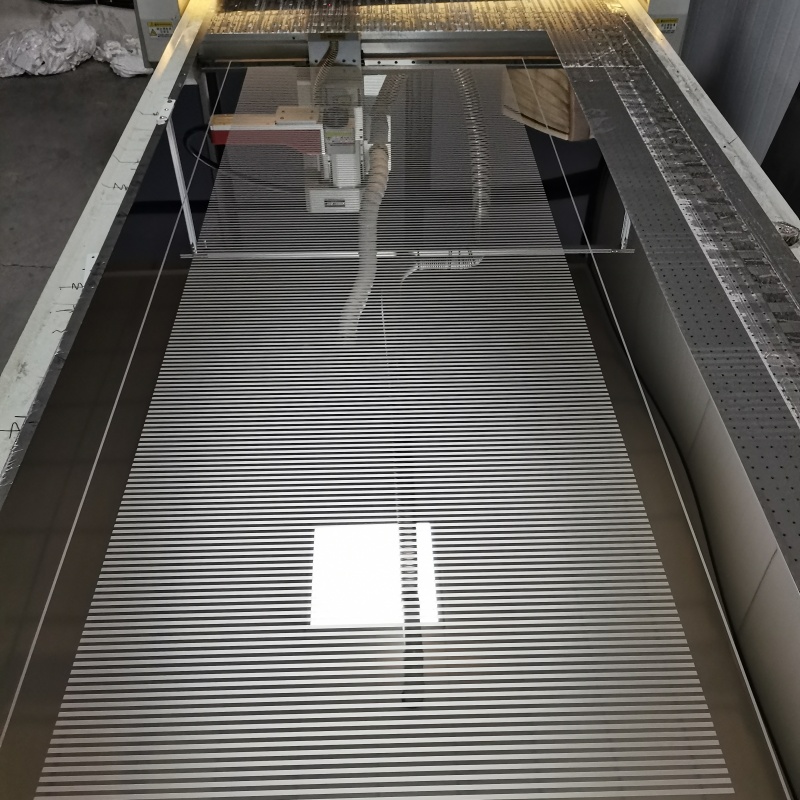

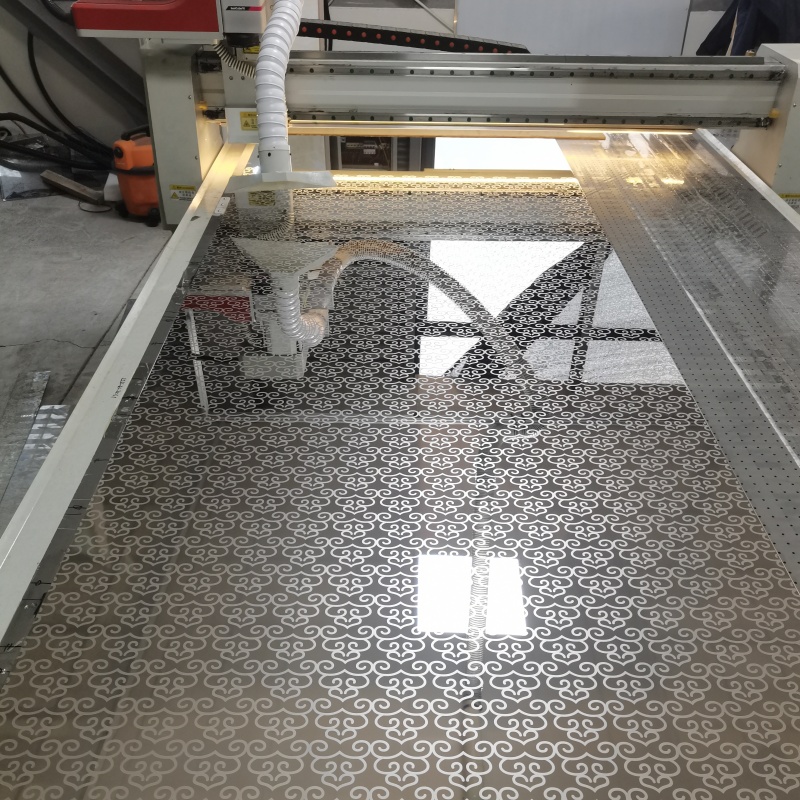

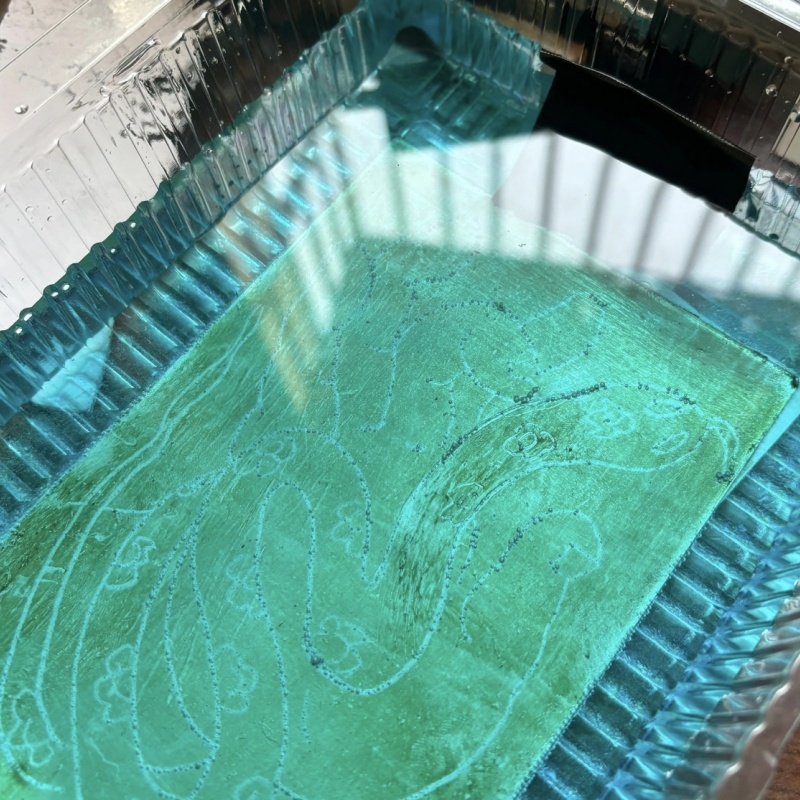

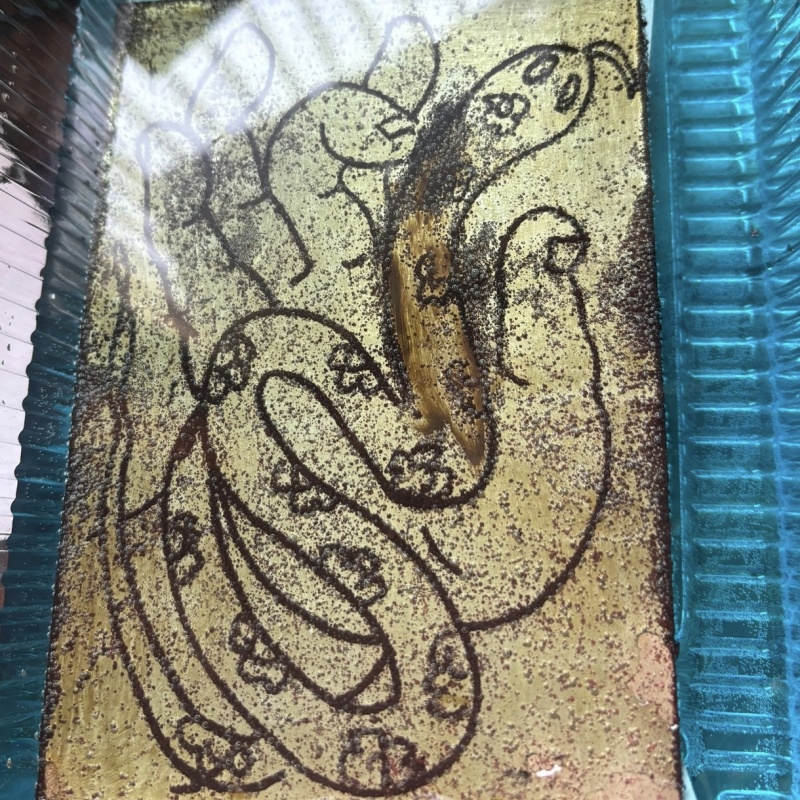

Laser etching technology uses a high-energy-density laser beam to irradiate the surface of the workpiece. Through the interaction between the laser and the material, the material is locally heated, melted, vaporized or chemically reacted, thereby achieving precise etching of the material. Traditional chemical etching uses chemical reactions to remove the part of the material surface that is not protected by the resist, thereby forming the desired pattern or structure on the material surface.

Laser Etching and Traditional Chemical Etching Processing Accuracy

Laser etching technology is known for its high precision and high stability. The laser beam can be focused to the micron or even nanometer level to achieve precise processing of the material surface. In contrast, the accuracy of traditional chemical etching is limited by the uniformity of the etching solution and the rate of chemical reaction, making it difficult to achieve such high-precision processing. Therefore, in fields that require high-precision processing, such as integrated circuit manufacturing, optical component manufacturing, etc., laser etching technology has significant advantages.

Laser Etching and Traditional Chemical Etching Production Cost

Laser etching technology also has obvious advantages in terms of production costs. First of all, laser etching equipment usually has a high degree of automation, which can achieve continuous and efficient production, thereby reducing labor costs. Secondly, no chemical reagents are required in the laser etching process, which avoids pollutants such as waste liquid and waste gas that may be generated in the chemical etching process, and reduces environmental protection costs. In addition, the yield rate of laser etching is high, which reduces material waste and scrap rate, and further reduces production costs.

Laser Etching and Traditional Chemical Etching Environmental Protection

Environmental protection is another significant advantage of laser etching technology over traditional chemical etching. The chemical reagents used in traditional chemical etching are often toxic or corrosive, posing a potential threat to the environment and human health. However, no chemical reagents are required in the laser etching process, which fundamentally avoids environmental pollution and human health risks. In addition, the waste generated in the laser etching process is less and easy to handle, which further improves its environmental protection.

Laser Etching and Traditional Chemical Etching Scope Of Application

Laser etching technology and traditional chemical etching technology each have their own scope of application. Traditional chemical etching technology is still widely used in photovoltaics, ceramics and other fields due to its wide adaptability and low cost. However, in fields that require high-precision and high-efficiency processing, such as integrated circuit manufacturing and optical component manufacturing, laser etching technology has gradually become mainstream with its advantages of high precision and high stability. In addition, laser etching technology is also widely used in touch screens, ITO films and other fields, providing strong support for the development of these fields.

The advantages of laser etching machines are significant:

Extremely high precision: It can reach micron level or even higher precision, and can etch patterns and texts in small spaces, meeting the stringent requirements of high precision in chip manufacturing, precision mechanical parts processing, etc.

Flexible customization: Through computer programming control, no expensive molds are required, and complex shapes and patterns can be easily etched, which is suitable for small batch, diversified and personalized product processing.

Non-contact processing: The laser beam focuses on the surface of the material, does not contact the material, and does not produce mechanical stress and deformation. It is suitable for thin, fragile, and easily deformed materials, such as plastic film, glass, etc.

Efficient processing: The processing speed is fast, and large-area etching can be completed in a short time. Simple patterns or regular shapes can be processed in batches at high speed to improve production efficiency.

Green and environmentally friendly: No chemical reagents are used in the processing, and there is no wastewater, waste gas, or waste residue pollution. The waste is mainly powder, which is easy to collect and treat.

Universal materials: It can etch a variety of materials such as metal, plastic, glass, ceramics, wood, leather, etc., and the parameters can be adjusted according to the characteristics of the material.

High-quality surface: after etching, the surface is smooth, the edges are neat, there are no burrs or gaps, and no subsequent grinding and polishing is required, which reduces costs.

Repeatable and stable: With good stability, as long as the parameters are set well, etching can be repeated accurately many times to ensure the consistency and reliability of large-scale production products.