Trends in metal cutting machines

—-Plasma

vs. Fiber laser

Who¡¯s better?

When discussing the trends of the plasma cutter and fiber laser cutter, the differences between these two machines are very important.

What Is Laser Cutting?

Laser cutting has long been regarded as a safe, efficient, and reliable cutting process. Laser cutting machines make use of high-powered, computer-operated lasers. The core component is an optical fiber that is equipped with elements such as erbium, thulium, and dysprosium. When used with nitrogen, oxygen, or compressed air, the fiber lasers can slice through a wide variety of metals with a high degree of precision. Laser cutting machines are often multipurpose and used for a variety of jobs.

What is Plasma Cutting?

The plasma cutter is one of the most fine-tuned and versatile tools used to slice heavy and thick materials more easily. Plasma cutting is performed by forcing compressed air and inert gases like hydrogen and nitrogen through a fine nozzle at high speeds. The combining of the gasses, the high speeds, and the concentrated area of pressure create plasma, an electrically conductive ionized gas.

Which to Choose?

¡ñCutting speed

|

Material |

Thickness(mm) |

Cutting speed (m/min) |

||

|

12KW Fiber laser |

20KW Fiber Laser |

300A Plasma |

||

|

Stainless steel |

12 |

4.5-6 |

7-9 |

3 |

|

14 |

2.5-3.5 |

5.5-7 |

2.67 |

|

|

20 |

1.1-1.6 |

2.5-3.5 |

1.93 |

|

|

25 |

0.65-1.1 |

1.5-1.8 |

1.43 |

|

|

30 |

0.25-0.6 |

1.0-1.5 |

1.08 |

|

|

40 |

0.15-0.2 |

0.45-0.65 |

0.45 |

|

|

Carbon steel |

12 |

3-5£¨air£© |

6-8£¨air£© |

3.94 |

|

14 |

2.5-4£¨air£© |

5-6.5£¨air£© |

3.44 |

|

|

20 |

1.2-1.5£¨O2£© |

2.2-2.8£¨air£© |

2.5 |

|

|

25 |

0.5-1.2£¨O2£© |

1.0-1.6£¨O2£© |

1.9 |

|

|

30 |

0.3-1.0£¨O2£© |

0.8-1.2£¨O2£© |

1.5 |

|

High-power fiber laser has almost the same cutting efficiency as plasma.

High-power fiber laser has much higher speed for thin and medium thickness sheet.

¡ñMaterial saving

|

Thickness |

20mm |

25mm |

30mm |

40mm |

|

|

Material cost compare

|

Plasma |

$0.57/m |

$0.7/m |

$0.85/m |

$1.1/m |

|

10KW+ Fiber laser |

$0.15/m |

$0.19/m |

$0.23/m |

$0.31/m |

|

|

Saving |

$0.41/m |

$0.52/m |

$0.6/m |

$0.83/m |

|

|

Note£ºMetal sheet price: $660/t£»Thickness¡Ý20mmmetal sheet£ºplasma cutting kerf 5-6mm£¬fiber laser cutting kerf 1.5mm |

|||||

Fiber laser cutting has smaller kerf, can save more materials, cutting more parts

¡ñ14mm/30mm carbon steel cutting cost analysis

|

Name of Cost |

Fiber laser£¨12KW£© |

Fiber laser£¨20KW£© |

Plasma£¨300A£© |

|

Consumables£¨USD/h£© |

0.7 |

0.7 |

10.5£¨electrode£¬nozzle£¬vortex ring£© |

|

Average power consumption£¨USD/h£© |

9 |

12 |

12 |

|

Oxygen£¨USD/h£© |

1.5 |

1.5 |

1.8 |

|

Carry£¨1person£©and polish£¨2 people£© |

0 |

0 |

9 |

|

Drill and locate£¬transport£¨3 people with machine£© |

0 |

0 |

9 |

|

Fixed cost£¨USD/h£© |

9.8£¨11.3£© |

12.8£¨14.3£© |

42.7 |

|

Cutting speed£¨14mmCS£© |

4m/min |

6m/min |

3.4m/min |

|

Operating costs per meter |

$0.04/m |

$0.3/m |

$0.2/m |

|

Cutting speed£¨30mmCS£© |

0.41m/min |

1.2m/min |

1.5m/min |

|

Operating costs per meter |

$0.46/m |

$0.2/m |

$0.47/m |

Fiber laser cutting has lower overall costs than plasma cutting

|

Parameter |

Fiber laser Cutter |

Plasma cutter |

Fiber laser advantages |

|

Positioning accuracy |

0.14mm£¨10m machine body£© |

0.4mm£¨10m machine body£© |

High precision |

|

Section verticality |

0.2mm£¨40mm thickness£© |

5mm£¨40mmthickness£© |

No need reprocess |

|

Kerf width |

0.2-1.6mm |

3-6.0mm |

Save material 5-8% |

|

Common edge width |

3-4mm |

10mm |

|

|

Heat affected zone |

0.1-0.4mm |

0.5-2.0mm |

Less heat absorption and less deformation |

|

Section quality |

Good, less slug |

normal |

No need polish |

|

Cutting speed(thin to medium thickness) |

Fast |

normal |

High production efficiency |

|

Cutting small holes |

diameter to depth ratio 20% |

Can not cut |

No need drill machine and transportation |

|

Environment |

Clean |

Smoky |

Environmental friendly |

Case : Perforated disc

|

Traditional processing |

12kW fiber laser |

20kW fiber laser |

|

|

Machinery |

300A plasma cutter¡¢ Deburring machine¡¢Milling machine¡¢drilling machine |

Fiber laser cutter |

Fiber laser cutter |

|

Stuff |

3 people |

1people |

1people |

|

Work station |

4£¨change 4 types drill£© |

1 |

1 |

|

Reprocessing or not |

Yes |

No need |

No need |

|

Cutting speed |

1.9m/min |

1.1m/min |

1.5m/min |

|

Processing time |

56min6s |

7min19s |

5min22s |

|

Plasma cutting£º4min14s£»Polishing£º38s£»Vertical milling£º1min34s; Drilling£º16min40s£»Work station change and transport£º33min£© |

|||

|

Cost |

$7.9 |

$1.39 |

$1.269 |

|

£¨Unit price£º$0.2/m¡¢contour length£º1.57m£»Unit hole price£º$0.15/hole£¬50holes£© |

£¨Unit price£º$0.17/m¡¢ contour length£º8.05m£© |

£¨Unit price£º$0.16/m contour length£º8.05m£© |

The trends of both machine

Plasma cutting keeps getting cheaper, faster, smarter, and more cost efficient, so more manufacturers are using the process as their primary way to cut through non-ferrous metals. Automated and portable plasma cutters are enabling even unskilled workers the chance to utilize the technology, and future developments may be able to create fully automated plasma cutting machines, with little to no human guidance.

Currently, plasma cutting is used in a variety of applications, most of them related to manufacturing. There are many different types of plasma cutters available to manufacturers, including both automatic and manual units, as well as handheld equipment for precision applications. But plasma cutting hasn¡¯t always been inexpensive and available, and the technology has room to grow in the future.

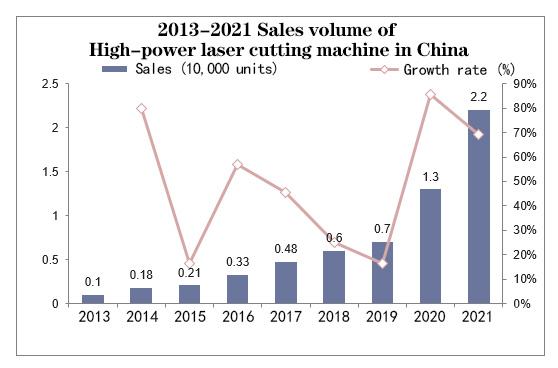

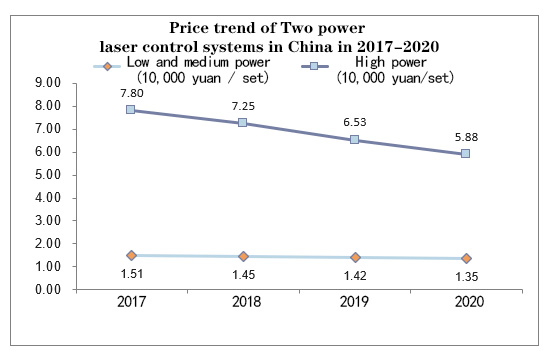

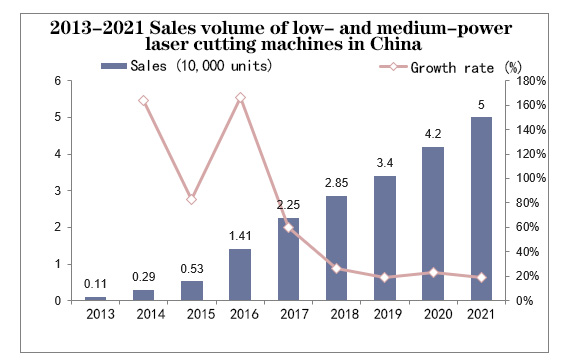

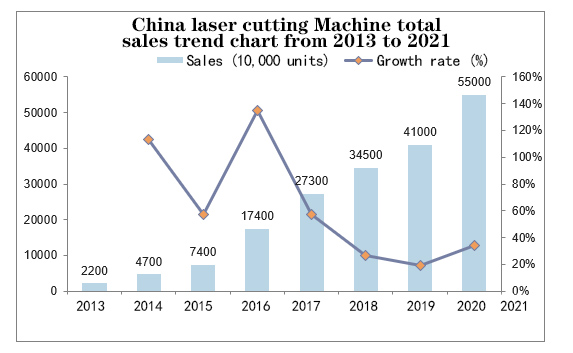

From above charts we can tell that in China market the sales volume of high-power laser cutting equipment reached 13,000 units, a significant increase of 85.7% year-on-year. Compared with low- and medium-power laser cutting equipment, the growth rate was higher, which had to benefit from the cost reduction brought by the continuous localization of fiber lasers.

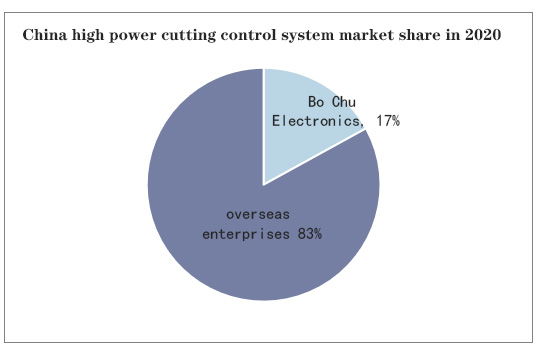

From the trend of the price for high-power laser cutting system, it can be foreseen that high power fiber laser cutting will continue to occupy more market shares. Most importantly, with the development of laser cutting technology, plasma will not the only holder of thick metal cutting market. Shorter piercing time and lower consumption of the fiber laser cutting machine will help it grow.

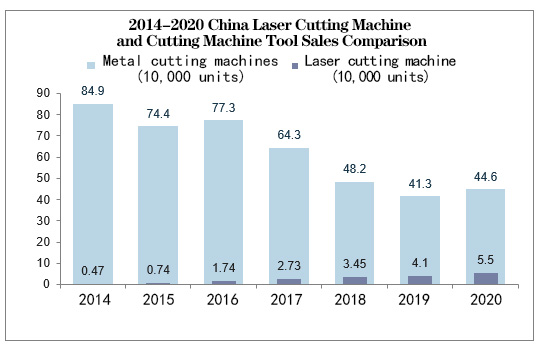

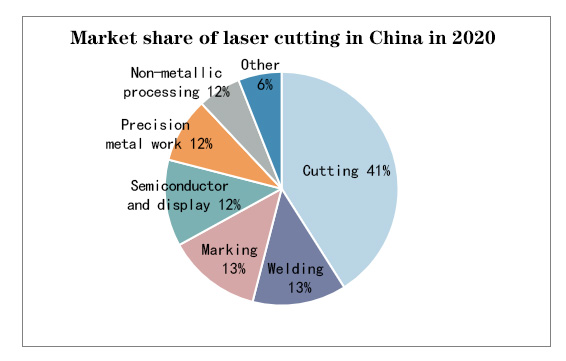

However, on the whole, laser cutting equipment is only 12.3% of the sales of metal cutting machine tools, and the penetration rate of laser cutting is relatively low, that is, the annual output of laser cutting machines accounts for the proportion of metal cutting machine tools. This shows that laser cutting machines gradually replace traditional cutting machine tools and develop rapidly.

We expect that the entire outlook of plasma cutting machines will undergo a transformation. A large section of the plasma cutting machine market will be taken over by laser machines and simultaneously, the improved plasma cutting machines will also take over a sll part of the present laser cutting market.

Generally speaking, now it¡¯s a good time for thick and thin thickness sheet metal fabricators to update their plasma to fiber laser. Because the era of Industry 4.0 has arrived, and high-end manufacturing is the future trend.