In the wave of precision manufacturing, laser etching technology has become a core support for product identification and processing. From micro-coding of electronic components to wear-resistant markings on industrial parts, from personalized engraving of cultural and creative products to aseptic etching of medical devices, choosing a reliable and efficient laser etching machine directly determines production efficiency and product quality. With over a decade of experience in laser technology, our laser etching machines have become the trusted choice of countless enterprises due to their four core advantages.

Ultimate precision, defining new heights of detail, is the core competitiveness of our products. The value of laser etching lies in “precision,” and we have maximized this characteristic. Our equipment uses an imported fiber laser generator, coupled with a high-precision servo drive system, achieving etching linewidths as low as 0.01 millimeters, equivalent to one-seventh the thickness of a human hair. Whether engraving complex circuit diagrams on stainless steel surfaces or creating tiny anti-counterfeiting marks on ceramic materials, we can achieve smooth edges and clear lines. Compared to traditional etching processes, our equipment completely solves the problems of edge burrs and pattern deformation that easily occur in chemical etching, and also avoids the physical damage to precision parts caused by mechanical engraving. In a practical application by an electronics company, after using our equipment, the chip pin marking qualification rate increased from 82% to 99.8%, significantly reducing rework costs.

High efficiency and energy saving empower production to reduce costs and increase efficiency, injecting new vitality into enterprises. In industrial production, efficiency and cost are eternal challenges. Our laser etching machine uses a self-developed high-speed scanning galvanometer, with an etching speed of up to 15,000 mm/s, 40% higher than the industry average. Taking the mass production of mobile phone casings as an example, the workload that traditional equipment takes 8 hours to complete can be completed by our equipment in just 5 hours, and it can operate continuously for 24 hours without failure. At the same time, the equipment is equipped with an intelligent power adjustment system that can automatically match the optimal laser power according to the material thickness, saving more than 30% energy compared to similar products. After introducing our equipment, an automotive parts manufacturer reduced its monthly electricity expenses by nearly 10,000 yuan. Coupled with the increased production capacity brought about by improved efficiency, the equipment investment cost was recovered within six months.

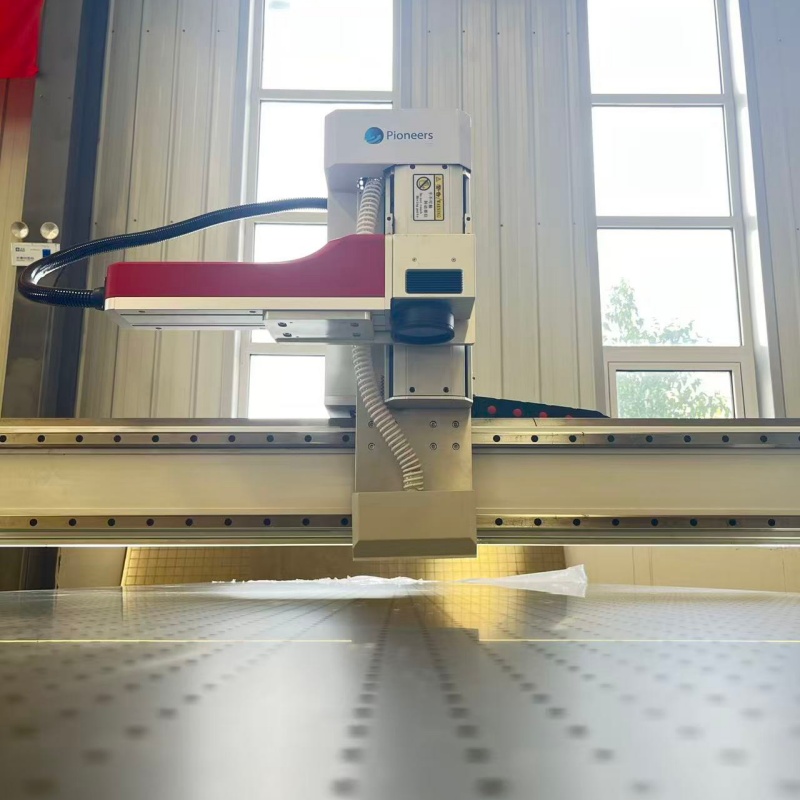

Diverse adaptability breaks material limitations and meets the needs of all scenarios. Etching needs vary widely across industries, from metals and plastics to glass and stone, from flexible films to hard alloys—our laser etching machines can handle them all with ease. The equipment has built-in preset parameters for 120 materials; operators simply select the corresponding material to quickly start processing. For special materials such as titanium alloy medical devices, we have specially developed a low-temperature etching mode, ensuring etching results while preventing material performance changes due to high temperatures. Customers in the cultural and creative industries use our equipment to carve delicate textures on wooden bookmarks and create 3D patterns on crystal ornaments, enriching their product range. Customers in the aerospace industry use the equipment to etch high-temperature resistant markings on high-temperature alloy components, ensuring clear and legible markings even in extreme environments.

Intelligent and convenient, lowering the operating threshold and ensuring stable operation. We always adhere to a “user-centric” design philosophy. The equipment is equipped with a 10-inch touchscreen, with a simple and intuitive interface; even beginners can operate it independently after half an hour of training. The built-in intelligent detection system can monitor key parameters such as laser power and lens temperature in real time. In case of abnormalities, it immediately stops the machine with an alarm and displays a troubleshooting solution on the screen. Meanwhile, the equipment supports remote operation and maintenance, allowing technicians to diagnose faults and update systems remotely via the network, significantly reducing repair time. A precision instrument factory once faced order delays due to a sudden equipment failure. Our technical team, through remote operation and maintenance, resolved the problem in just two hours, ensuring on-time order delivery.

From technology research and development to manufacturing, from pre-sales consultation to after-sales service, we consistently hold ourselves to the highest standards. Choosing our laser etching machine is not just choosing a piece of equipment, but choosing a reliable partner. On the road to precision manufacturing, we will work hand in hand with you, using precise etching, efficient production capacity, and attentive service to help your products stand out in market competition and create a better future together.