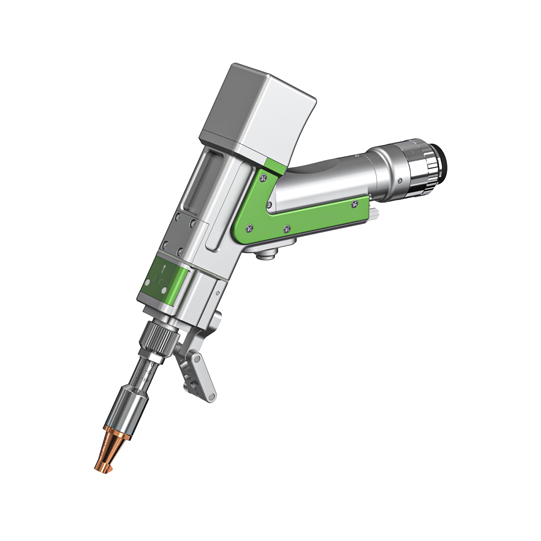

Handheld laser welding machines have become increasingly popular in recent years due to their versatility and efficiency in the welding process. These machines offer numerous advantages over traditional welding methods, including increased precision, speed, and flexibility. In this article, we will explore the advantages of handheld laser welding machines and discuss their future market potential.

Advantages of Handheld Laser Welding Machines

Increased Precision: One of the main advantages of handheld laser welding machines is their ability to provide precise and accurate welds. The laser beam can be focused to a very small spot, allowing for greater control over the welding process. This precision also reduces the amount of material needed for the weld, resulting in less waste and cost savings.

Speed: Handheld laser welding machines can weld at a much faster rate than traditional welding methods. The high energy density of the laser beam allows for quick heating and cooling of the material, resulting in faster welding times. This speed can help to increase productivity and reduce overall production time.

Flexibility: Handheld laser welding machines are extremely versatile and can be used to weld a wide range of materials, including metals, plastics, and even some ceramics. They are also capable of welding materials of varying thicknesses, making them suitable for a wide range of applications.

Reduced Heat Affected Zone (HAZ): Another advantage of handheld laser welding machines is their ability to minimize the heat affected zone (HAZ) during the welding process. The laser beam heats the material quickly and precisely, resulting in less heat being transferred to the surrounding area. This reduces the likelihood of warping or distortion in the material and can also result in a cleaner, more precise weld.

Ease of Use: Handheld laser welding machines are designed to be user-friendly and easy to operate. They typically feature a simple interface and can be controlled with a handheld remote, making them easy to use even for inexperienced operators.

Future Market Potential

The future market potential for handheld laser welding machines is significant, as they offer numerous advantages over traditional welding methods. The increasing demand for high-quality, precise welding in industries such as automotive, aerospace, and electronics is driving the growth of the handheld laser welding machine market.

In addition, the trend towards automation and Industry 4.0 is also driving the growth of the market. Handheld laser welding machines can be easily integrated into automated production lines, offering increased efficiency and productivity.

The growing focus on sustainability and reducing waste is also expected to drive the growth of the handheld laser welding machine market. The precise nature of the laser welding process results in less material waste, reducing overall production costs and minimizing the impact on the environment.

Overall, the future market potential for handheld laser welding machines is promising, as they offer numerous advantages over traditional welding methods and are well-suited to meet the demands of the modern manufacturing industry.

Conclusion

Handheld laser welding machines offer numerous advantages over traditional welding methods, including increased precision, speed, flexibility, and reduced HAZ. The future market potential for these machines is significant, driven by the increasing demand for high-quality, precise welding, the trend towards automation and Industry 4.0, and the growing focus on sustainability and reducing waste. As such, the use of handheld laser welding machines is likely to become increasingly prevalent in the manufacturing industry in the coming years.